Maximizing Efficiency with Rotary Lobe Pumps in Meat and Poultry Processing

May 09,2025

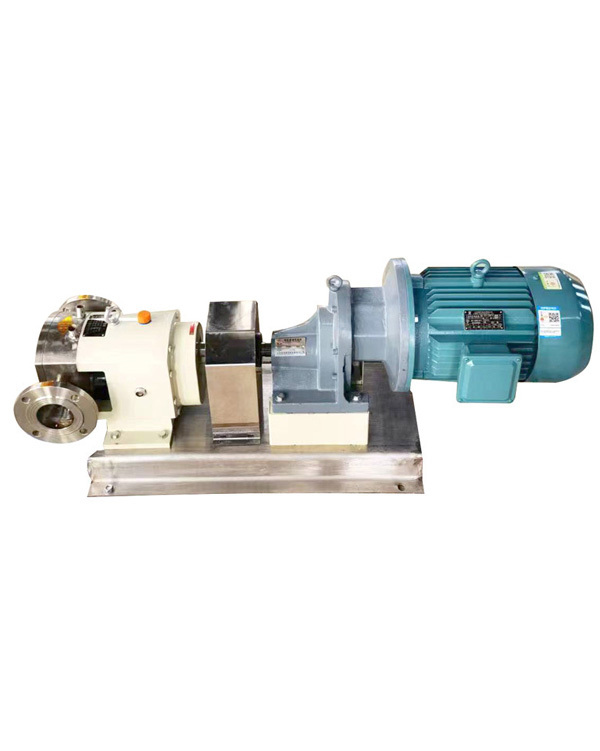

In the meat and poultry processing industry, maintaining product integrity while ensuring efficient operations is paramount. Rotary lobe pumps have emerged as a preferred choice for this sector, owing to their unique design and operational advantages. These pumps consist of two or more lobes that rotate in a synchronized manner, creating a cavity that moves the fluid through the pump. This mechanism allows rotary lobe pumps to handle various types of materials, including viscous and shear-sensitive products, making them highly versatile.

One of the primary benefits of rotary lobe pumps is their ability to maintain hygiene and cleanliness during processing. The design of the pump minimizes dead zones where bacteria can grow, ensuring that the product remains uncontaminated. This is especially critical in meat and poultry processing, where strict hygiene standards must be adhered to. Additionally, many rotary lobe pumps can be easily disassembled for cleaning, further enhancing their suitability for food processing applications.

The gentle handling of products is another significant advantage. Unlike other pump types that may shear or damage sensitive materials, rotary lobe pumps provide a smooth flow and low shear, preserving the quality of meat and poultry products. This makes them ideal for transferring delicate items like ground meats or emulsified products without compromising texture or flavor.

Energy efficiency is also a key consideration in industrial operations. Rotary lobe pumps are designed to operate efficiently over a range of flow rates, which can lead to lower energy consumption compared to traditional pump systems. By optimizing the operational parameters, businesses can reduce their overall energy costs while maintaining high output levels.

In terms of maintenance, rotary lobe pumps are relatively straightforward to service. With fewer moving parts than centrifugal pumps, they often require less frequent maintenance and can have longer service intervals. This reliability reduces downtime, which is crucial in the fast-paced meat and poultry processing environment.

Moreover, rotary lobe pumps can be customized to meet specific application needs. Different materials, sizes, and configurations can be chosen to accommodate various production requirements, ensuring that processors can find a solution that fits their unique operations.

In summary, rotary lobe pumps offer a range of advantages for meat and poultry processing, including hygiene maintenance, gentle product handling, energy efficiency, and ease of maintenance. As the industry continues to evolve, incorporating advanced pumping solutions like rotary lobe pumps will be essential for processors looking to enhance operational efficiency and product quality while adhering to stringent safety standards.

One of the primary benefits of rotary lobe pumps is their ability to maintain hygiene and cleanliness during processing. The design of the pump minimizes dead zones where bacteria can grow, ensuring that the product remains uncontaminated. This is especially critical in meat and poultry processing, where strict hygiene standards must be adhered to. Additionally, many rotary lobe pumps can be easily disassembled for cleaning, further enhancing their suitability for food processing applications.

The gentle handling of products is another significant advantage. Unlike other pump types that may shear or damage sensitive materials, rotary lobe pumps provide a smooth flow and low shear, preserving the quality of meat and poultry products. This makes them ideal for transferring delicate items like ground meats or emulsified products without compromising texture or flavor.

Energy efficiency is also a key consideration in industrial operations. Rotary lobe pumps are designed to operate efficiently over a range of flow rates, which can lead to lower energy consumption compared to traditional pump systems. By optimizing the operational parameters, businesses can reduce their overall energy costs while maintaining high output levels.

In terms of maintenance, rotary lobe pumps are relatively straightforward to service. With fewer moving parts than centrifugal pumps, they often require less frequent maintenance and can have longer service intervals. This reliability reduces downtime, which is crucial in the fast-paced meat and poultry processing environment.

Moreover, rotary lobe pumps can be customized to meet specific application needs. Different materials, sizes, and configurations can be chosen to accommodate various production requirements, ensuring that processors can find a solution that fits their unique operations.

In summary, rotary lobe pumps offer a range of advantages for meat and poultry processing, including hygiene maintenance, gentle product handling, energy efficiency, and ease of maintenance. As the industry continues to evolve, incorporating advanced pumping solutions like rotary lobe pumps will be essential for processors looking to enhance operational efficiency and product quality while adhering to stringent safety standards.

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai