Understanding Rotary Lobe Pumps for High-Viscosity Liquids

Jun 26,2025

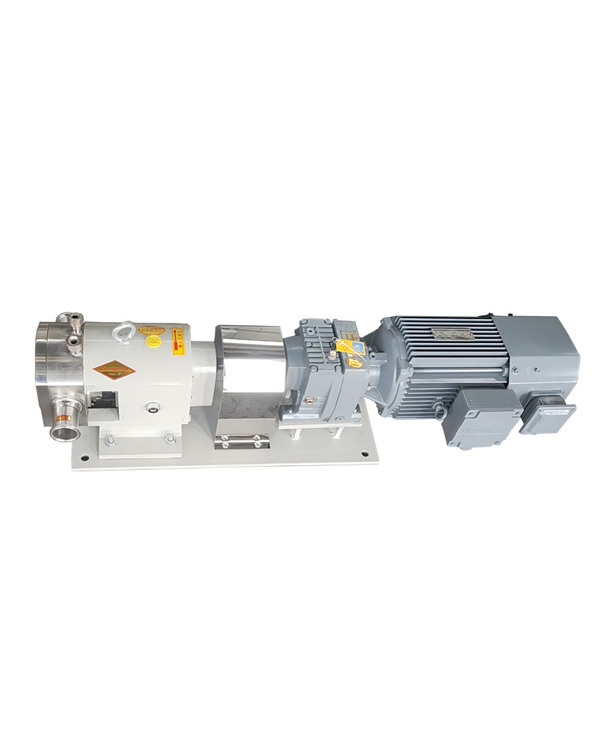

Rotary lobe pumps are a vital component in the industrial sector, especially when it comes to transferring high-viscosity liquids. Their unique design and operational capabilities make them an ideal choice for a range of applications, from food processing to chemical manufacturing. The following discussion highlights key features, benefits, and operational considerations associated with rotary lobe pumps for high-viscosity liquids.

At the core of rotary lobe pumps is their mechanism, which employs two or more lobes that rotate in a synchronized manner. This design allows the pump to move high-viscosity liquids with minimal shear, maintaining the integrity of the fluid being pumped. For industries dealing with materials such as pastes, slurries, and thick oils, this attribute is essential as it prevents degradation of the product while ensuring efficient flow.

One of the significant advantages of rotary lobe pumps is their ability to handle varying viscosities without compromising performance. Their flow rate is relatively constant, which means that these pumps can maintain efficiency across a wide range of operating conditions. Additionally, they offer a self-priming capability, which is particularly beneficial in applications where the fluid source may be below the pump level.

Another noteworthy feature is the ease of maintenance associated with rotary lobe pumps. Many models are designed with quick-disassembly features, allowing for straightforward cleaning and servicing. This is crucial in industries like food and pharmaceuticals, where hygiene is paramount. Regular maintenance not only extends the lifespan of the pump but also ensures consistent performance, preventing unexpected downtimes.

When selecting a rotary lobe pump for high-viscosity liquids, it is important to consider factors such as the material compatibility of pump components, as well as the operating temperature and pressure requirements. The materials used in the construction of the pump should withstand the specific characteristics of the liquid being handled, including any abrasive or corrosive properties.

Moreover, the installation and positioning of the pump play a critical role in optimizing its performance. Ensuring that the pump is correctly aligned and mounted can prevent unnecessary wear and tear, as well as potential operational inefficiencies. Furthermore, employing proper piping systems can minimize pressure losses and improve overall system efficiency.

In conclusion, rotary lobe pumps are a robust solution for the transportation of high-viscosity liquids across various industries. Their operational efficiency, ease of maintenance, and suitability for handling a range of fluid characteristics make them an indispensable tool in modern industrial applications. By understanding the advantages and considerations of using rotary lobe pumps, businesses can enhance their processes, ensure product quality, and ultimately increase their operational efficiency.

At the core of rotary lobe pumps is their mechanism, which employs two or more lobes that rotate in a synchronized manner. This design allows the pump to move high-viscosity liquids with minimal shear, maintaining the integrity of the fluid being pumped. For industries dealing with materials such as pastes, slurries, and thick oils, this attribute is essential as it prevents degradation of the product while ensuring efficient flow.

One of the significant advantages of rotary lobe pumps is their ability to handle varying viscosities without compromising performance. Their flow rate is relatively constant, which means that these pumps can maintain efficiency across a wide range of operating conditions. Additionally, they offer a self-priming capability, which is particularly beneficial in applications where the fluid source may be below the pump level.

Another noteworthy feature is the ease of maintenance associated with rotary lobe pumps. Many models are designed with quick-disassembly features, allowing for straightforward cleaning and servicing. This is crucial in industries like food and pharmaceuticals, where hygiene is paramount. Regular maintenance not only extends the lifespan of the pump but also ensures consistent performance, preventing unexpected downtimes.

When selecting a rotary lobe pump for high-viscosity liquids, it is important to consider factors such as the material compatibility of pump components, as well as the operating temperature and pressure requirements. The materials used in the construction of the pump should withstand the specific characteristics of the liquid being handled, including any abrasive or corrosive properties.

Moreover, the installation and positioning of the pump play a critical role in optimizing its performance. Ensuring that the pump is correctly aligned and mounted can prevent unnecessary wear and tear, as well as potential operational inefficiencies. Furthermore, employing proper piping systems can minimize pressure losses and improve overall system efficiency.

In conclusion, rotary lobe pumps are a robust solution for the transportation of high-viscosity liquids across various industries. Their operational efficiency, ease of maintenance, and suitability for handling a range of fluid characteristics make them an indispensable tool in modern industrial applications. By understanding the advantages and considerations of using rotary lobe pumps, businesses can enhance their processes, ensure product quality, and ultimately increase their operational efficiency.

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai