The Essential Role of Rotary Lobe Pumps in Meat and Poultry Processing

Feb 25,2025

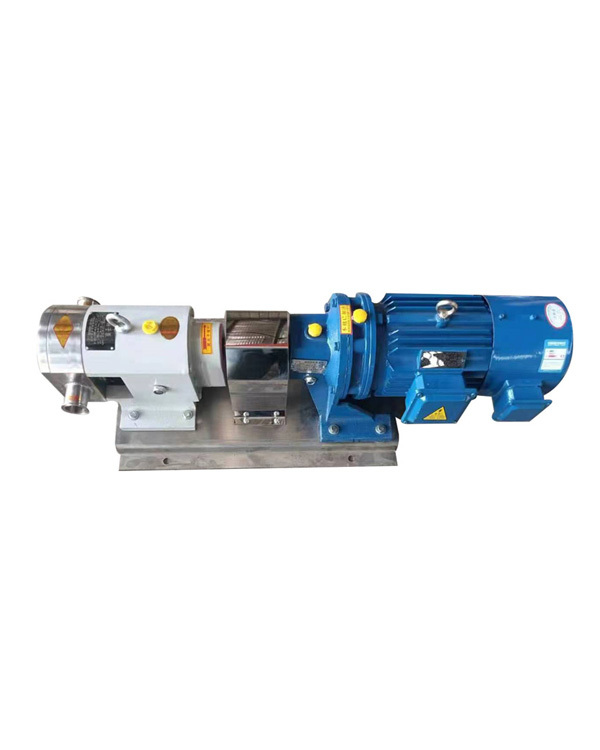

Rotary lobe pumps are crucial components in the meat and poultry processing sector, thanks to their unique design and efficient operational capabilities. These pumps are particularly valued for their ability to handle viscous and delicate fluids, making them ideal for transporting meat slurries, brines, and marinades without damaging the product’s integrity.

One of the key features of rotary lobe pumps is their non-contacting rotor design. This allows for gentle handling of materials, which is essential when dealing with meat and poultry products that require careful processing. The lobes rotate in a synchronized manner, creating pockets that trap the fluid and move it through the pump. This design minimizes shear rates, preserving the quality and structure of the meat during transit.

In addition to their gentle handling capabilities, rotary lobe pumps are highly versatile. They can accommodate a wide range of flow rates and pressures, making them suitable for various applications across the meat and poultry processing industry. Whether it's transferring raw materials or pumping finished products, these pumps can be tailored to meet specific operational needs, enhancing overall efficiency.

Hygiene is another critical aspect of meat and poultry processing, and rotary lobe pumps are designed with this in mind. Many models feature easy-to-clean designs, which are essential for maintaining sanitary conditions in food processing facilities. With smooth surfaces and minimal crevices, these pumps can be thoroughly cleaned and sanitized, thus helping to prevent contamination and ensure food safety.

Efficiency is paramount in any industrial setting, and rotary lobe pumps deliver reliable performance even under demanding conditions. They are capable of handling varying viscosities and can even manage solids in suspension, making them suitable for applications such as pumping minced meat or processing by-products. This adaptability not only improves operational efficiency but also reduces downtime caused by equipment failures or maintenance.

Moreover, energy efficiency is a notable advantage of rotary lobe pumps. They typically require less energy to operate compared to other pump types, which can lead to significant cost savings over time. Their robust construction and reliable performance mean fewer replacements and less frequent maintenance, further contributing to their economic benefits.

In conclusion, rotary lobe pumps are indispensable in the meat and poultry processing industry. Their gentle handling, versatility, hygienic design, and operational efficiency make them a preferred choice for manufacturers looking to optimize their production processes. By utilizing rotary lobe pumps, businesses can ensure that their products maintain high quality while also adhering to safety standards, ultimately leading to increased customer satisfaction.

One of the key features of rotary lobe pumps is their non-contacting rotor design. This allows for gentle handling of materials, which is essential when dealing with meat and poultry products that require careful processing. The lobes rotate in a synchronized manner, creating pockets that trap the fluid and move it through the pump. This design minimizes shear rates, preserving the quality and structure of the meat during transit.

In addition to their gentle handling capabilities, rotary lobe pumps are highly versatile. They can accommodate a wide range of flow rates and pressures, making them suitable for various applications across the meat and poultry processing industry. Whether it's transferring raw materials or pumping finished products, these pumps can be tailored to meet specific operational needs, enhancing overall efficiency.

Hygiene is another critical aspect of meat and poultry processing, and rotary lobe pumps are designed with this in mind. Many models feature easy-to-clean designs, which are essential for maintaining sanitary conditions in food processing facilities. With smooth surfaces and minimal crevices, these pumps can be thoroughly cleaned and sanitized, thus helping to prevent contamination and ensure food safety.

Efficiency is paramount in any industrial setting, and rotary lobe pumps deliver reliable performance even under demanding conditions. They are capable of handling varying viscosities and can even manage solids in suspension, making them suitable for applications such as pumping minced meat or processing by-products. This adaptability not only improves operational efficiency but also reduces downtime caused by equipment failures or maintenance.

Moreover, energy efficiency is a notable advantage of rotary lobe pumps. They typically require less energy to operate compared to other pump types, which can lead to significant cost savings over time. Their robust construction and reliable performance mean fewer replacements and less frequent maintenance, further contributing to their economic benefits.

In conclusion, rotary lobe pumps are indispensable in the meat and poultry processing industry. Their gentle handling, versatility, hygienic design, and operational efficiency make them a preferred choice for manufacturers looking to optimize their production processes. By utilizing rotary lobe pumps, businesses can ensure that their products maintain high quality while also adhering to safety standards, ultimately leading to increased customer satisfaction.

NEXT:

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai