Enhancing Meat and Poultry Processing with Rotary Lobe Pumps

Mar 07,2025

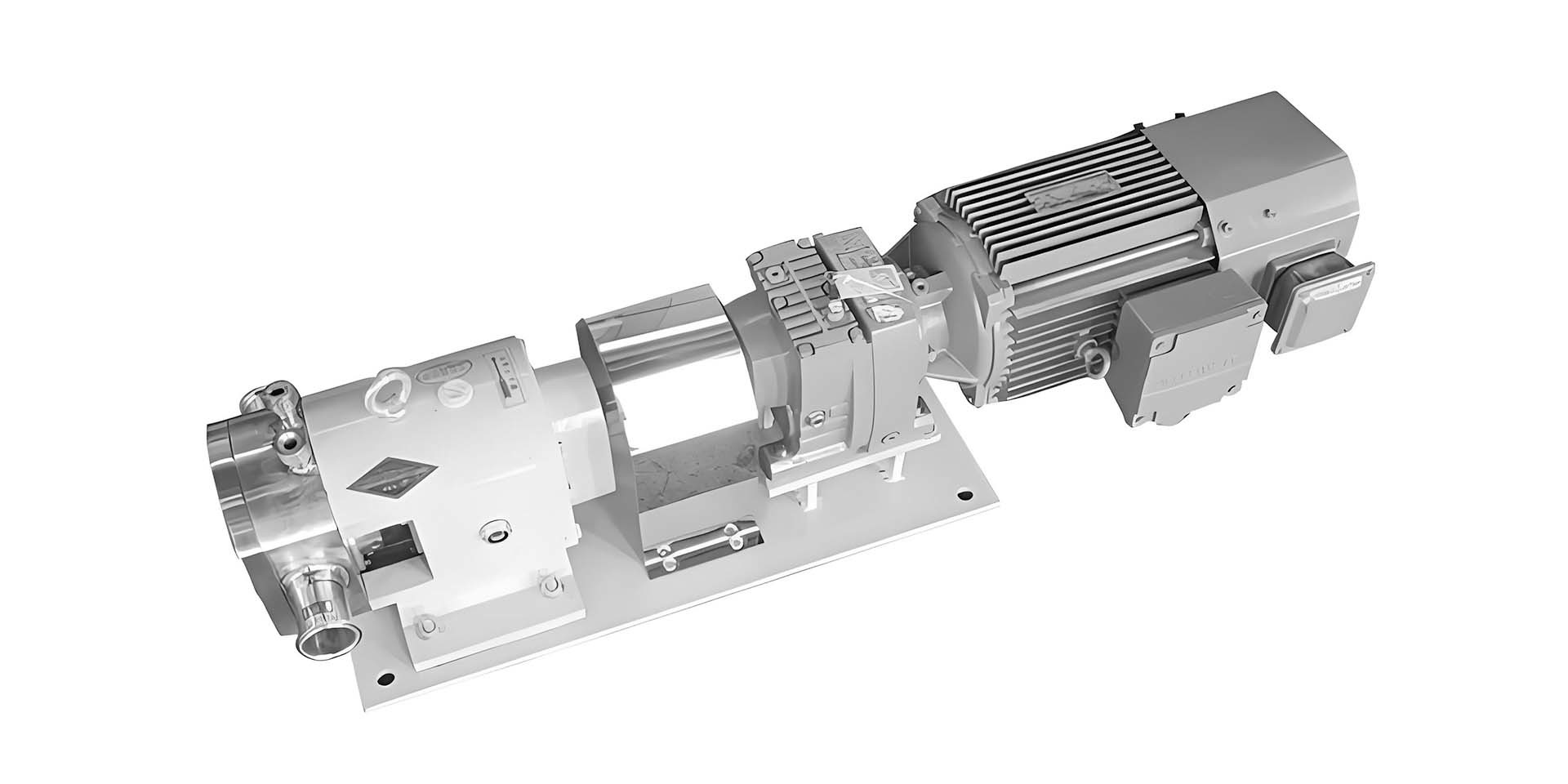

Rotary lobe pumps have emerged as a vital component in the meat and poultry processing industry, primarily due to their reliability and versatility in handling various types of fluids and materials. These positive displacement pumps are designed to move products with minimal shear, making them ideal for transferring sensitive meat products without compromising their integrity.

One of the key advantages of rotary lobe pumps is their ability to handle a wide range of viscosities, which is particularly important in meat and poultry processing where products can vary significantly in texture and consistency. Whether dealing with thick marinades, purees, or even delicate emulsions, these pumps can maintain consistent flow rates and pressure, ensuring that the processing line operates smoothly.

In addition to their versatility, rotary lobe pumps are designed to be hygienic and easy to clean, which is essential in the food processing industry. The construction materials are often compliant with food safety standards, and the design typically allows for quick disassembly, facilitating thorough cleaning and maintenance. This is critical in preventing cross-contamination and ensuring the safety of the final product.

Furthermore, the operational efficiency of rotary lobe pumps can lead to reduced downtime and maintenance costs. Their robust design tends to require fewer repairs compared to other pump types, and they can handle abrasive materials without significant wear and tear. This reliability is particularly beneficial in high-demand processing environments where continuous operation is necessary.

Another important aspect of rotary lobe pumps is their ability to operate quietly, which contributes to a better working environment. Noise reduction is often an overlooked factor in industrial settings but can lead to improved worker productivity and comfort.

When integrating rotary lobe pumps into meat and poultry processing operations, it is essential to consider factors such as pump size, material compatibility, and the specific requirements of the processing line. Proper selection and installation can optimize performance and enhance product quality.

In summary, rotary lobe pumps are an indispensable tool in the meat and poultry processing industry. Their unique characteristics, including versatility, hygienic design, operational efficiency, and low noise levels, make them an excellent choice for processors looking to improve their operations. By ensuring that the right pump is chosen for the specific application, processors can achieve significant improvements in product handling and overall efficiency, ultimately leading to a more successful operation.

One of the key advantages of rotary lobe pumps is their ability to handle a wide range of viscosities, which is particularly important in meat and poultry processing where products can vary significantly in texture and consistency. Whether dealing with thick marinades, purees, or even delicate emulsions, these pumps can maintain consistent flow rates and pressure, ensuring that the processing line operates smoothly.

In addition to their versatility, rotary lobe pumps are designed to be hygienic and easy to clean, which is essential in the food processing industry. The construction materials are often compliant with food safety standards, and the design typically allows for quick disassembly, facilitating thorough cleaning and maintenance. This is critical in preventing cross-contamination and ensuring the safety of the final product.

Furthermore, the operational efficiency of rotary lobe pumps can lead to reduced downtime and maintenance costs. Their robust design tends to require fewer repairs compared to other pump types, and they can handle abrasive materials without significant wear and tear. This reliability is particularly beneficial in high-demand processing environments where continuous operation is necessary.

Another important aspect of rotary lobe pumps is their ability to operate quietly, which contributes to a better working environment. Noise reduction is often an overlooked factor in industrial settings but can lead to improved worker productivity and comfort.

When integrating rotary lobe pumps into meat and poultry processing operations, it is essential to consider factors such as pump size, material compatibility, and the specific requirements of the processing line. Proper selection and installation can optimize performance and enhance product quality.

In summary, rotary lobe pumps are an indispensable tool in the meat and poultry processing industry. Their unique characteristics, including versatility, hygienic design, operational efficiency, and low noise levels, make them an excellent choice for processors looking to improve their operations. By ensuring that the right pump is chosen for the specific application, processors can achieve significant improvements in product handling and overall efficiency, ultimately leading to a more successful operation.

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai