Exploring the Advantages of Using Rotary Lobe Pumps in Molasses Transfer

Jun 17,2025

Exploring the Advantages of Using Rotary Lobe Pumps in Molasses Transfer

Table of Contents

- Introduction to Rotary Lobe Pumps

- What Are Rotary Lobe Pumps?

- How Do Rotary Lobe Pumps Work?

- Advantages of Using Rotary Lobe Pumps in Molasses Transfer

- High Efficiency and Reliability

- Gentle Handling of Viscous Fluids

- Versatility in Applications

- Easy Maintenance and Cleanliness

- Cost-Effectiveness in the Long Run

- Applications of Rotary Lobe Pumps in Various Industries

- Conclusion

- FAQs

Introduction to Rotary Lobe Pumps

In the world of industrial equipment, the type of pump used can significantly impact the efficiency and quality of material handling. **Rotary lobe pumps** have emerged as a popular choice for transferring viscous fluids like molasses. Understanding their unique advantages can help businesses make informed decisions that enhance operational efficiency and product integrity.

What Are Rotary Lobe Pumps?

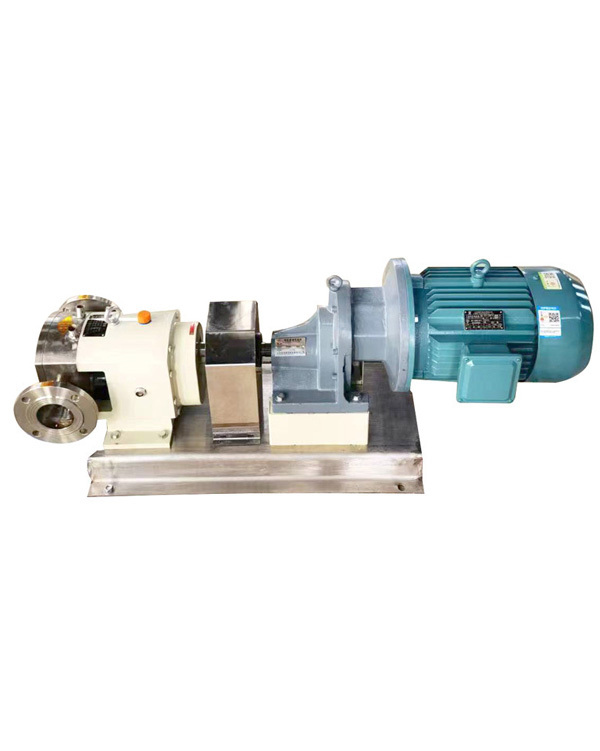

Rotary lobe pumps are positive displacement pumps designed to move viscous materials with minimal shear and turbulence. They consist of two or more lobes that rotate in opposite directions, creating cavities that draw in and expel fluid. This mechanism allows for the effective transfer of thick materials such as molasses, ensuring a consistent flow rate and pressure.

How Do Rotary Lobe Pumps Work?

The operation of rotary lobe pumps involves several key components: **rotors, housing, and drive system**. As the lobes rotate within the pump casing, they create expanding and contracting spaces. Here's a breakdown of the process:

1. **Fluid Introduction**: As the lobes rotate outward, they create a vacuum that draws molasses into the pump.

2. **Fluid Transport**: The lobes then rotate back, pushing the molasses forward through the discharge port.

3. **Continuous Flow**: This action continues, providing a steady flow of material without pulsation.

This design ensures that even the most viscous materials are moved effectively, making rotary lobe pumps ideal for molasses transfer and other heavy fluids.

Advantages of Using Rotary Lobe Pumps in Molasses Transfer

High Efficiency and Reliability

Rotary lobe pumps are renowned for their high efficiency. They maintain a consistent flow rate, which is crucial for **molasses transfer** processes that demand precision. The pump's design minimizes energy consumption, ensuring that your operations remain both reliable and cost-effective.

Gentle Handling of Viscous Fluids

One of the standout features of rotary lobe pumps is their ability to handle viscous fluids gently. The non-contact operation of the lobes reduces the shear stress on the fluid, preserving the quality of molasses. This gentle handling is essential in the food and beverage industry, where product integrity is paramount.

Versatility in Applications

These pumps are not limited to the transfer of molasses alone. They are versatile enough to handle a broad range of liquids, including slurries, pastes, and other viscous materials. This adaptability makes rotary lobe pumps suitable for various industries, including food processing, pharmaceuticals, and petrochemicals.

Easy Maintenance and Cleanliness

Maintaining rotary lobe pumps is relatively straightforward. Their design allows for easy access to key components, facilitating regular maintenance and cleaning. The **sanitary options** available for these pumps ensure compliance with health regulations, making them perfect for industries that prioritize hygiene.

Cost-Effectiveness in the Long Run

While the initial investment in rotary lobe pumps may be higher than that of other pump types, their long-term benefits outweigh the upfront costs. Their durability, low maintenance requirements, and energy efficiency contribute to significant cost savings over time, enhancing their value proposition for businesses.

Applications of Rotary Lobe Pumps in Various Industries

Rotary lobe pumps find applications across numerous industries due to their efficiency and adaptability. Here are some key sectors where these pumps are making a significant impact:

1. **Food and Beverage Industry**: In addition to molasses, rotary lobe pumps are used for transferring syrups, sauces, and even dairy products, thanks to their gentle handling capabilities.

2. **Pharmaceuticals**: The ability to manage viscous fluids and ensure sanitary conditions makes these pumps ideal for transferring creams, ointments, and other pharmaceutical products.

3. **Cosmetics**: Similar to the pharmaceutical industry, the cosmetics sector benefits from rotary lobe pumps for transferring thick lotions and creams.

4. **Chemical Processing**: Rotary lobe pumps are proficient in handling various chemicals, including adhesives and paints, making them essential in chemical manufacturing processes.

Conclusion

Rotary lobe pumps present a multitude of advantages for the transfer of molasses and other viscous materials. Their high efficiency, gentle handling, versatility, and easy maintenance make them an excellent choice for various industries. By investing in rotary lobe pumps, businesses can enhance operational efficiency, maintain product quality, and achieve significant cost savings over time.

FAQs

1. What makes rotary lobe pumps suitable for handling molasses?

Rotary lobe pumps are designed to handle viscous fluids with minimal shear and turbulence, ensuring the integrity of molasses during transfer.

2. How do rotary lobe pumps compare to other types of pumps?

Unlike other pumps, rotary lobe pumps provide a gentle, consistent flow and are highly efficient in transferring thick fluids, making them ideal for applications involving molasses.

3. Are rotary lobe pumps easy to maintain?

Yes, rotary lobe pumps are designed for easy access to critical components, simplifying maintenance and cleaning processes.

4. Can rotary lobe pumps be used in food processing?

Absolutely! Rotary lobe pumps are widely used in food processing due to their ability to maintain product integrity and comply with sanitary standards.

5. What are the long-term cost benefits of using rotary lobe pumps?

While they may have a higher initial cost, rotary lobe pumps offer durability, energy efficiency, and low maintenance costs, leading to significant savings over time.

PREVIOUS:

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai