Unlocking Efficiency: How Rotary Lobe Pumps Enhance Syrup and Molasses Processing

Mar 10,2025

Unlocking Efficiency: How Rotary Lobe Pumps Enhance Syrup and Molasses Processing

Table of Contents

1. Introduction to Rotary Lobe Pumps

2. Understanding Syrup and Molasses Processing

3. The Mechanism of Rotary Lobe Pumps

3.1 How Rotary Lobe Pumps Work

3.2 Key Components of Rotary Lobe Pumps

4. Advantages of Using Rotary Lobe Pumps in Processing

4.1 Enhanced Efficiency and Reliability

4.2 Gentle Handling of Viscous Fluids

4.3 Easy Maintenance and Operation

5. Applications in Syrup and Molasses Processing

5.1 Transferring High-Viscosity Products

5.2 Mixing and Metering

6. Comparing Rotary Lobe Pumps with Other Pump Types

6.1 Centrifugal Pumps vs. Rotary Lobe Pumps

6.2 Progressive Cavity Pumps vs. Rotary Lobe Pumps

7. Key Considerations When Choosing a Rotary Lobe Pump

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to Rotary Lobe Pumps

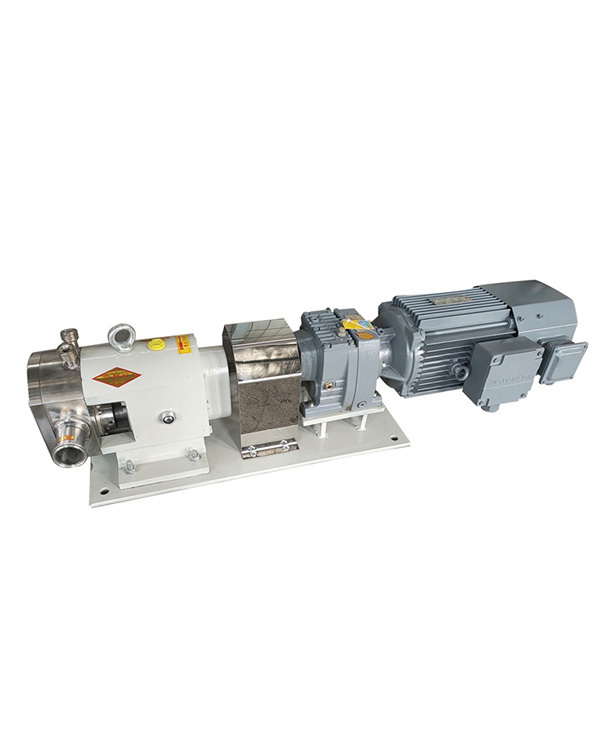

Rotary lobe pumps are a vital component in the industrial processing of syrups and molasses. Unlike traditional pump systems, these pumps operate on a positive displacement mechanism, which allows for consistent and accurate flow rates. This unique operation is especially beneficial in industries where product integrity and efficiency are paramount.

2. Understanding Syrup and Molasses Processing

Syrup and molasses production involves the extraction of sugars from plants, predominantly sugarcane and sugar beets. This process includes several stages, from extraction and clarification to concentration and packaging. The viscosity of syrup and molasses can vary significantly, making the choice of pump critical for efficient processing.

3. The Mechanism of Rotary Lobe Pumps

3.1 How Rotary Lobe Pumps Work

Rotary lobe pumps consist of two or more lobes that rotate in opposite directions. As the lobes turn, they create a vacuum that draws the liquid into the pump chamber. The liquid is then trapped between the lobes and the casing, allowing for a smooth transfer to the discharge side.

3.2 Key Components of Rotary Lobe Pumps

Key components of a rotary lobe pump include:

- **Lobes**: Typically made from high wear-resistant materials, ensuring durability.

- **Casing**: Designed to contain the moving lobes while providing an efficient flow path.

- **Drive Mechanism**: Often powered by an electric motor, this mechanism ensures precise control over the pump's operation.

4. Advantages of Using Rotary Lobe Pumps in Processing

4.1 Enhanced Efficiency and Reliability

Rotary lobe pumps are renowned for their reliability and efficiency. They handle varying viscosities with ease, ensuring consistent flow rates even under challenging conditions. This efficiency translates into reduced downtime and increased productivity.

4.2 Gentle Handling of Viscous Fluids

One of the standout features of rotary lobe pumps is their ability to handle viscous materials without damaging them. The design minimizes shear forces, making them ideal for sensitive products like syrup and molasses that can be adversely affected by aggressive pumping methods.

4.3 Easy Maintenance and Operation

Maintenance of rotary lobe pumps is straightforward. Their modular design allows for easy access to components, reducing the time and effort required for repairs and replacements. Additionally, the simplicity of operation minimizes the risk of human error, ensuring that production processes run smoothly.

5. Applications in Syrup and Molasses Processing

5.1 Transferring High-Viscosity Products

In syrup and molasses processing, transferring high-viscosity products from one stage to another is critical. Rotary lobe pumps excel in this application, providing dependable flow rates and maintaining product quality throughout the transfer process.

5.2 Mixing and Metering

Beyond just transferring liquids, rotary lobe pumps can be utilized for mixing and metering applications. Their capacity for precise flow control allows manufacturers to create consistent blends of syrup and other ingredients, ensuring uniformity in the final product.

6. Comparing Rotary Lobe Pumps with Other Pump Types

6.1 Centrifugal Pumps vs. Rotary Lobe Pumps

While centrifugal pumps are common in various industries, they struggle with viscous fluids. In contrast, rotary lobe pumps provide a superior solution for syrup and molasses processing, where maintaining product integrity is crucial.

6.2 Progressive Cavity Pumps vs. Rotary Lobe Pumps

Progressive cavity pumps are often used in similar applications, yet they may require more maintenance due to their complex design. Rotary lobe pumps stand out for their user-friendly setup and operational simplicity, making them a preferred choice for many processors.

7. Key Considerations When Choosing a Rotary Lobe Pump

When selecting a rotary lobe pump for syrup and molasses processing, consider factors such as:

- **Viscosity Range**: Ensure the pump can handle the specific viscosity of your product.

- **Material Compatibility**: Select materials that resist wear and corrosion from the product being pumped.

- **Flow Rate Requirements**: Determine the necessary flow rate for your production line and choose a pump that meets these needs.

8. Frequently Asked Questions (FAQs)

What are the benefits of using rotary lobe pumps in syrup processing?

Rotary lobe pumps offer consistent flow rates, gentle handling of viscous products, and easy maintenance, all contributing to enhanced efficiency in syrup processing.

How do rotary lobe pumps compare to centrifugal pumps?

Unlike centrifugal pumps, rotary lobe pumps excel at handling viscous fluids, offering better performance in syrup and molasses processing.

What maintenance is required for rotary lobe pumps?

Routine maintenance includes checking the seals, lubricating moving parts, and ensuring the lobes are free from wear and damage.

Can rotary lobe pumps be used for mixing applications?

Yes, rotary lobe pumps are effective for mixing applications, providing precise flow control for uniform blending of ingredients.

What industries benefit from using rotary lobe pumps?

Industries such as food and beverage, pharmaceuticals, and chemicals benefit greatly from the efficiency and reliability of rotary lobe pumps.

9. Conclusion

In conclusion, **rotary lobe pumps** represent a game-changing technology in the **syrup and molasses processing** industry. Their ability to handle high-viscosity products with efficiency and precision makes them an invaluable asset for manufacturers. By understanding the advantages and applications of rotary lobe pumps, businesses can unlock new levels of operational efficiency and product quality, ensuring they remain competitive in the market. Embracing this technology not only enhances processing capabilities but also contributes to overall cost savings and improved customer satisfaction.

PREVIOUS:

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai