Understanding Rotary Lobe Pumps for High-Viscosity Liquids: Efficiency and Functionality

Mar 13,2025

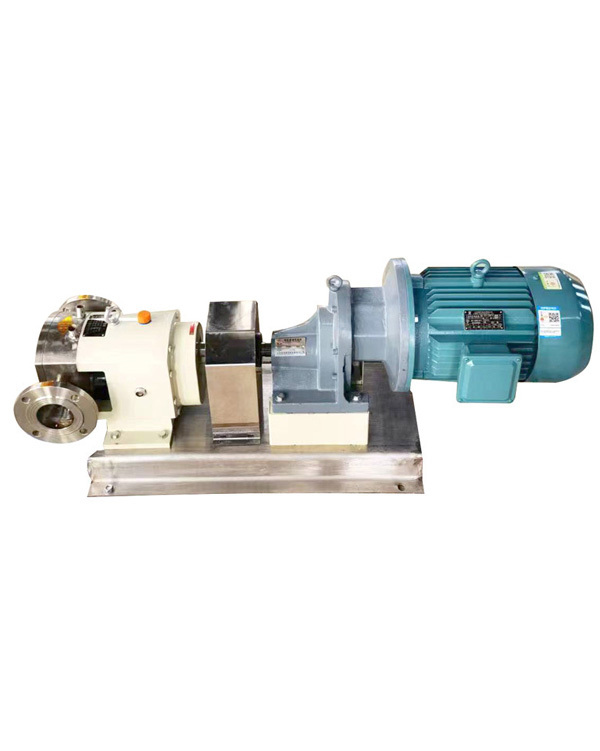

Rotary lobe pumps are positive displacement pumps that employ two or more lobes to move liquids efficiently. They are particularly designed for handling high-viscosity liquids, making them an essential choice in various industries such as food and beverage, pharmaceuticals, and chemical processing. The unique design of these pumps allows them to maintain a consistent flow rate, regardless of the liquid’s viscosity, making them exceptionally versatile.

One of the key operational features of rotary lobe pumps is their ability to create a vacuum-like effect that helps in drawing in the fluid. As the lobes rotate, they create chambers that expand and contract, thereby moving the liquid from the inlet to the outlet. This mechanism ensures that the pump can handle thick materials, slurries, and other non-Newtonian fluids with minimal shearing and damage, preserving the integrity of the liquid being pumped.

The efficiency of rotary lobe pumps is further enhanced by their design, which allows for easy maintenance and cleaning. Many models feature a design that minimizes dead zones, reducing the risk of product contamination—a critical factor in industries like food processing and pharmaceuticals. Additionally, they can operate at varying speeds, allowing for adjustable flow rates to meet specific application requirements.

In terms of applications, rotary lobe pumps are widely used for transferring materials such as oils, pastes, and other viscous fluids. Their ability to handle varying viscosities without compromising performance makes them a preferred choice in manufacturing processes that require precise flow control. Industries also appreciate the pump’s ability to handle shear-sensitive materials, as the low shear environment helps maintain product quality.

Another notable advantage of rotary lobe pumps is their energy efficiency. Since they operate based on positive displacement, they require less energy to move high-viscosity liquids compared to other pump types. This can result in significant cost savings and a reduced environmental footprint for businesses looking to improve their sustainability practices.

In conclusion, rotary lobe pumps are a reliable and effective solution for industries dealing with high-viscosity liquids. Their unique design and operational capabilities not only enhance efficiency but also ensure safety and product integrity. As industries continue to innovate and evolve, the role of rotary lobe pumps will likely become even more significant, making them an essential component in modern industrial applications.

One of the key operational features of rotary lobe pumps is their ability to create a vacuum-like effect that helps in drawing in the fluid. As the lobes rotate, they create chambers that expand and contract, thereby moving the liquid from the inlet to the outlet. This mechanism ensures that the pump can handle thick materials, slurries, and other non-Newtonian fluids with minimal shearing and damage, preserving the integrity of the liquid being pumped.

The efficiency of rotary lobe pumps is further enhanced by their design, which allows for easy maintenance and cleaning. Many models feature a design that minimizes dead zones, reducing the risk of product contamination—a critical factor in industries like food processing and pharmaceuticals. Additionally, they can operate at varying speeds, allowing for adjustable flow rates to meet specific application requirements.

In terms of applications, rotary lobe pumps are widely used for transferring materials such as oils, pastes, and other viscous fluids. Their ability to handle varying viscosities without compromising performance makes them a preferred choice in manufacturing processes that require precise flow control. Industries also appreciate the pump’s ability to handle shear-sensitive materials, as the low shear environment helps maintain product quality.

Another notable advantage of rotary lobe pumps is their energy efficiency. Since they operate based on positive displacement, they require less energy to move high-viscosity liquids compared to other pump types. This can result in significant cost savings and a reduced environmental footprint for businesses looking to improve their sustainability practices.

In conclusion, rotary lobe pumps are a reliable and effective solution for industries dealing with high-viscosity liquids. Their unique design and operational capabilities not only enhance efficiency but also ensure safety and product integrity. As industries continue to innovate and evolve, the role of rotary lobe pumps will likely become even more significant, making them an essential component in modern industrial applications.

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai