Optimizing Meat and Poultry Processing with Rotary Lobe Pumps

Mar 27,2025

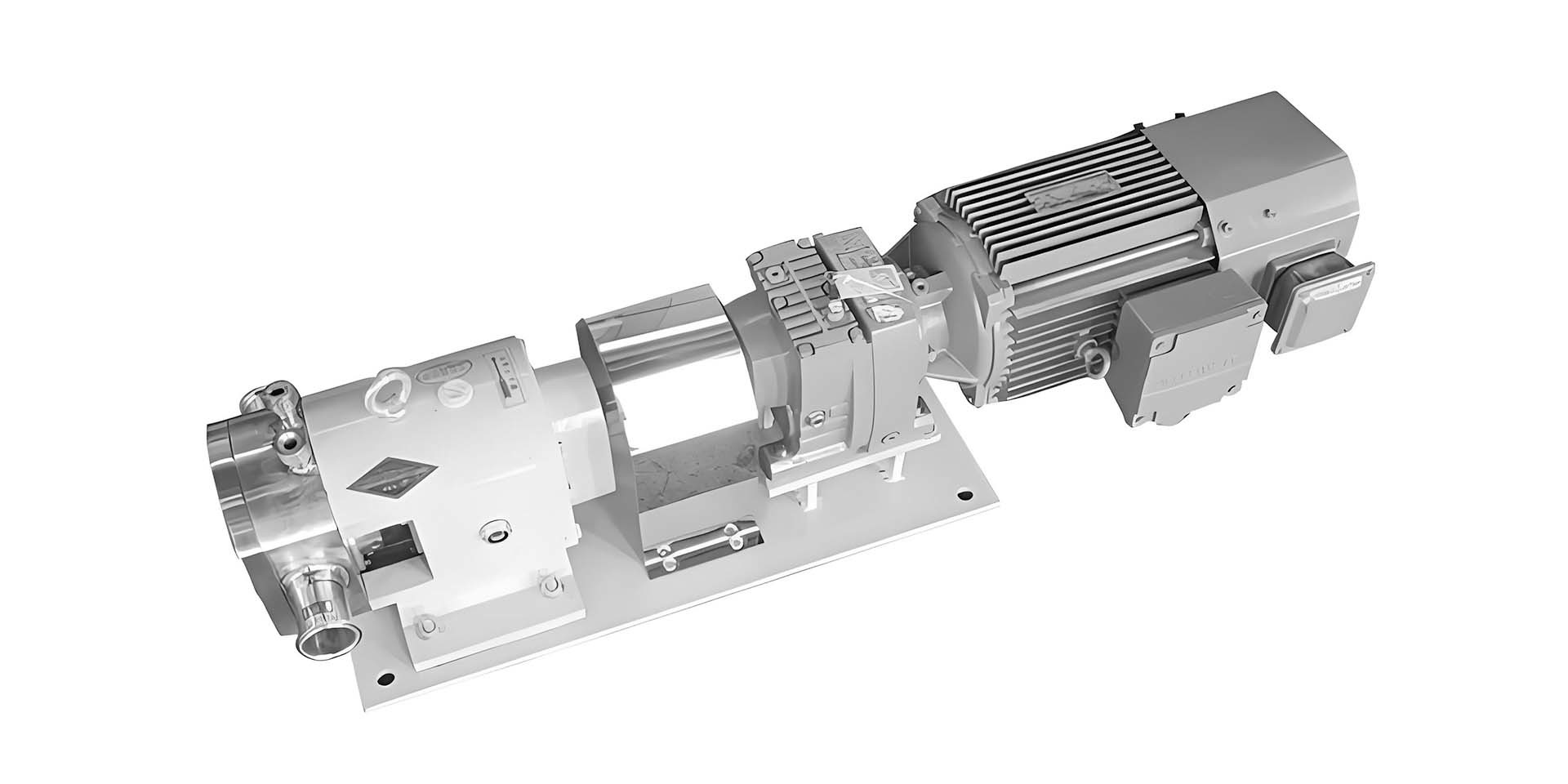

In the meat and poultry processing industry, maintaining product quality and safety is paramount. Rotary lobe pumps are increasingly recognized for their effectiveness in handling various fluids, making them an essential piece of equipment in this sector. These pumps are particularly advantageous due to their ability to gently transfer viscous materials, ensuring product integrity during processing.

One of the primary benefits of rotary lobe pumps in meat and poultry processing is their positive displacement mechanism. This feature allows for precise flow rates and consistent pressure, which are critical for maintaining the quality of meat products. Unlike centrifugal pumps, which can damage delicate materials due to shear forces, rotary lobe pumps operate with minimal impact on the fluid, preserving the texture and quality of the meat. This makes them ideal for transferring products such as purees, emulsions, and even whole pieces of meat.

In addition to their gentle handling capabilities, rotary lobe pumps are designed for easy cleaning and maintenance. The food industry is subject to stringent hygiene standards, and these pumps can be disassembled easily for thorough cleaning. Many models are also constructed from stainless steel, a material that resists corrosion and can withstand the rigorous cleaning processes required in food production.

Another significant advantage of rotary lobe pumps is their versatility. They can handle a wide range of viscosities and are suitable for various applications within meat and poultry processing, including marinating, brining, and transferring meat mixtures. This adaptability allows processing facilities to streamline operations and improve overall efficiency.

Moreover, rotary lobe pumps can operate effectively in both continuous and batch processing scenarios. This flexibility is essential in a dynamic production environment where processing demands may vary. By implementing rotary lobe pumps, companies can optimize their workflows, reduce downtime, and enhance production output.

It's also worth noting that energy efficiency is a growing concern in the food processing industry. Rotary lobe pumps are designed to minimize energy consumption while maximizing performance, making them an eco-friendly choice. Reduced energy costs not only lower operational expenses but also contribute to a company’s commitment to sustainability.

In conclusion, rotary lobe pumps are indispensable in the meat and poultry processing industry due to their ability to maintain product quality, streamline operations, and enhance energy efficiency. By investing in these pumps, processors can ensure they meet industry standards while delivering high-quality products to consumers. As the demand for efficient and safe processing methods continues to grow, rotary lobe pumps will remain at the forefront of innovation in food production.

One of the primary benefits of rotary lobe pumps in meat and poultry processing is their positive displacement mechanism. This feature allows for precise flow rates and consistent pressure, which are critical for maintaining the quality of meat products. Unlike centrifugal pumps, which can damage delicate materials due to shear forces, rotary lobe pumps operate with minimal impact on the fluid, preserving the texture and quality of the meat. This makes them ideal for transferring products such as purees, emulsions, and even whole pieces of meat.

In addition to their gentle handling capabilities, rotary lobe pumps are designed for easy cleaning and maintenance. The food industry is subject to stringent hygiene standards, and these pumps can be disassembled easily for thorough cleaning. Many models are also constructed from stainless steel, a material that resists corrosion and can withstand the rigorous cleaning processes required in food production.

Another significant advantage of rotary lobe pumps is their versatility. They can handle a wide range of viscosities and are suitable for various applications within meat and poultry processing, including marinating, brining, and transferring meat mixtures. This adaptability allows processing facilities to streamline operations and improve overall efficiency.

Moreover, rotary lobe pumps can operate effectively in both continuous and batch processing scenarios. This flexibility is essential in a dynamic production environment where processing demands may vary. By implementing rotary lobe pumps, companies can optimize their workflows, reduce downtime, and enhance production output.

It's also worth noting that energy efficiency is a growing concern in the food processing industry. Rotary lobe pumps are designed to minimize energy consumption while maximizing performance, making them an eco-friendly choice. Reduced energy costs not only lower operational expenses but also contribute to a company’s commitment to sustainability.

In conclusion, rotary lobe pumps are indispensable in the meat and poultry processing industry due to their ability to maintain product quality, streamline operations, and enhance energy efficiency. By investing in these pumps, processors can ensure they meet industry standards while delivering high-quality products to consumers. As the demand for efficient and safe processing methods continues to grow, rotary lobe pumps will remain at the forefront of innovation in food production.

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai