Understanding Rotary Lobe Pumps for High-Viscosity Liquids: An Essential Guide

Apr 02,2025

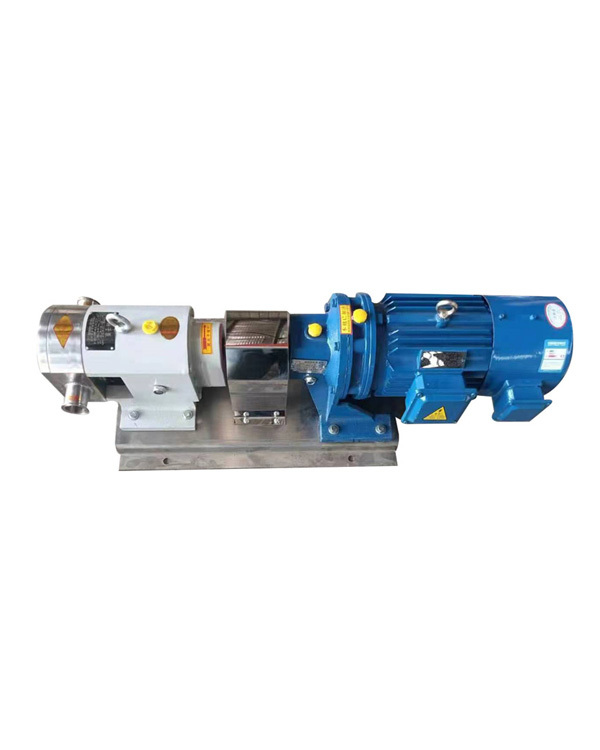

Rotary lobe pumps are a vital component in various industrial applications, particularly when it comes to handling high-viscosity liquids. These pumps utilize a unique design that allows them to effectively manage thick, non-Newtonian fluids that are often challenging for traditional pumping systems. Here, we explore the fundamental aspects of rotary lobe pumps, emphasizing their functionality, benefits, and common applications.

At the core of a rotary lobe pump's operation are lobes that rotate within a casing, creating a series of chambers that facilitate the movement of liquid. This mechanism allows for a gentle pumping action, which is particularly advantageous for high-viscosity liquids that could be damaged by more abrasive pumping methods. The design minimizes shear stress, making it ideal for sensitive materials such as food products, pharmaceuticals, and polymers.

One of the standout features of rotary lobe pumps is their ability to handle a wide range of viscosities. Whether it’s a thick paste or a viscous slurry, these pumps can be adjusted to accommodate the specific needs of the application. This flexibility not only improves efficiency but also enhances the overall reliability of the pumping process.

The benefits of using rotary lobe pumps for high-viscosity liquids extend beyond just their operational efficiency. For instance, these pumps are easy to clean and maintain due to their simple construction. This is particularly important in industries where hygiene standards are stringent, such as food processing and pharmaceuticals. The ability to disassemble and clean the pump thoroughly helps in maintaining product integrity and reduces the risk of contamination.

In addition to efficiency and hygiene, rotary lobe pumps are also known for their durability. Constructed from robust materials, these pumps can withstand the demanding environments often found in industrial settings. Their design also allows for a long lifespan, minimizing the need for frequent replacements and repairs.

Applications for rotary lobe pumps are diverse and span across various industries. In the food industry, they are commonly used for transferring sauces, jams, and other viscous products. In the pharmaceutical sector, these pumps facilitate the movement of ointments and gels. Additionally, industries dealing with chemicals, wastewater, and adhesives also benefit from the reliable performance of rotary lobe pumps.

In conclusion, rotary lobe pumps are a critical solution for effectively handling high-viscosity liquids across multiple sectors. Their unique design, operational efficiency, ease of maintenance, and durability make them a preferred choice among professionals seeking reliable pumping solutions. Understanding their functionalities and applications can empower industrial players to optimize their operations and enhance product handling processes efficiently.

At the core of a rotary lobe pump's operation are lobes that rotate within a casing, creating a series of chambers that facilitate the movement of liquid. This mechanism allows for a gentle pumping action, which is particularly advantageous for high-viscosity liquids that could be damaged by more abrasive pumping methods. The design minimizes shear stress, making it ideal for sensitive materials such as food products, pharmaceuticals, and polymers.

One of the standout features of rotary lobe pumps is their ability to handle a wide range of viscosities. Whether it’s a thick paste or a viscous slurry, these pumps can be adjusted to accommodate the specific needs of the application. This flexibility not only improves efficiency but also enhances the overall reliability of the pumping process.

The benefits of using rotary lobe pumps for high-viscosity liquids extend beyond just their operational efficiency. For instance, these pumps are easy to clean and maintain due to their simple construction. This is particularly important in industries where hygiene standards are stringent, such as food processing and pharmaceuticals. The ability to disassemble and clean the pump thoroughly helps in maintaining product integrity and reduces the risk of contamination.

In addition to efficiency and hygiene, rotary lobe pumps are also known for their durability. Constructed from robust materials, these pumps can withstand the demanding environments often found in industrial settings. Their design also allows for a long lifespan, minimizing the need for frequent replacements and repairs.

Applications for rotary lobe pumps are diverse and span across various industries. In the food industry, they are commonly used for transferring sauces, jams, and other viscous products. In the pharmaceutical sector, these pumps facilitate the movement of ointments and gels. Additionally, industries dealing with chemicals, wastewater, and adhesives also benefit from the reliable performance of rotary lobe pumps.

In conclusion, rotary lobe pumps are a critical solution for effectively handling high-viscosity liquids across multiple sectors. Their unique design, operational efficiency, ease of maintenance, and durability make them a preferred choice among professionals seeking reliable pumping solutions. Understanding their functionalities and applications can empower industrial players to optimize their operations and enhance product handling processes efficiently.

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai