Maximizing Efficiency: The Role of Rotary Lobe Pumps in Meat and Poultry Processing

Oct 09,2025

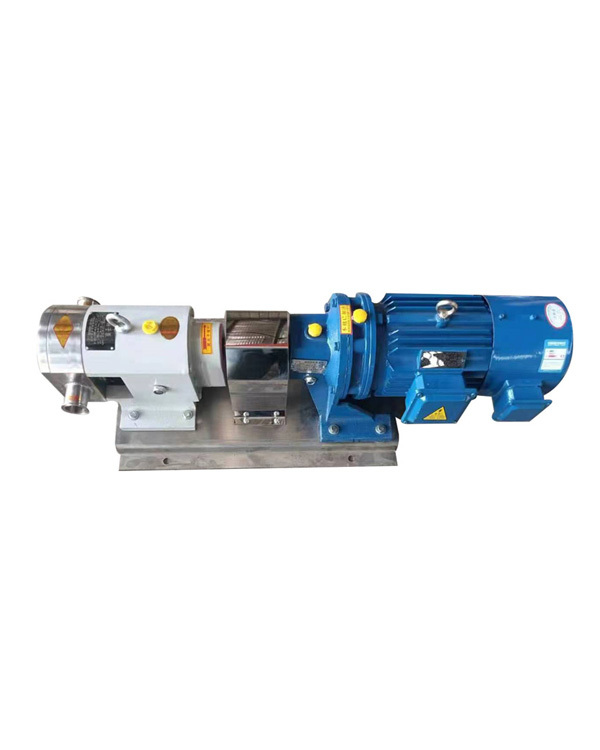

In the meat and poultry processing industry, maintaining efficiency and quality is paramount. One of the critical components that help achieve this is the rotary lobe pump. These pumps are known for their unique design and operational capabilities, making them ideal for transferring various products, including viscous and chunky materials.

Rotary lobe pumps function through the use of two or more lobes that rotate in synchronization. This design enables the pump to create a consistent flow while minimizing shear, which is particularly important when handling sensitive food products. The gentle pumping action ensures that the integrity and quality of the meat and poultry are preserved during processing.

One of the main advantages of rotary lobe pumps is their versatility. They can handle a wide range of products, from liquid slurries to solids, making them suitable for different stages of meat and poultry processing. Whether it’s transferring marinades, sauces, or ground meats, these pumps can provide reliable performance. This versatility allows processors to streamline operations, thereby increasing productivity and reducing downtime.

Hygiene is a critical concern in food processing. Rotary lobe pumps are designed with cleanability in mind. Many models feature smooth surfaces and minimal crevices, which help prevent the accumulation of bacteria and other contaminants. Additionally, they can be disassembled quickly for thorough cleaning, ensuring compliance with strict hygiene regulations in the food industry. This attribute is especially important in the meat and poultry sector, where food safety is of utmost importance.

Another significant benefit of rotary lobe pumps is their ability to handle varying flow rates and pressures. This adaptability enables processors to fine-tune their operations according to production requirements. By adjusting the pump's speed and settings, companies can effectively manage their workflows, which is essential for meeting market demands without compromising quality.

Moreover, rotary lobe pumps are known for their durability and reliability. Constructed from high-quality materials, they can withstand the demanding conditions of meat and poultry processing, including temperature variations and corrosive cleaning agents. This longevity translates into lower maintenance costs and less frequent replacements, which can significantly enhance overall operational efficiency.

In conclusion, rotary lobe pumps play a vital role in meat and poultry processing by providing gentle, efficient, and hygienic product transfer. Their versatility, ease of cleaning, and robustness make them an invaluable asset in modern food processing facilities. For businesses looking to optimize their operations, investing in rotary lobe pumps can lead to improved productivity and enhanced product quality. Understanding these benefits can help decision-makers in the industry make informed choices that align with their operational goals.

Rotary lobe pumps function through the use of two or more lobes that rotate in synchronization. This design enables the pump to create a consistent flow while minimizing shear, which is particularly important when handling sensitive food products. The gentle pumping action ensures that the integrity and quality of the meat and poultry are preserved during processing.

One of the main advantages of rotary lobe pumps is their versatility. They can handle a wide range of products, from liquid slurries to solids, making them suitable for different stages of meat and poultry processing. Whether it’s transferring marinades, sauces, or ground meats, these pumps can provide reliable performance. This versatility allows processors to streamline operations, thereby increasing productivity and reducing downtime.

Hygiene is a critical concern in food processing. Rotary lobe pumps are designed with cleanability in mind. Many models feature smooth surfaces and minimal crevices, which help prevent the accumulation of bacteria and other contaminants. Additionally, they can be disassembled quickly for thorough cleaning, ensuring compliance with strict hygiene regulations in the food industry. This attribute is especially important in the meat and poultry sector, where food safety is of utmost importance.

Another significant benefit of rotary lobe pumps is their ability to handle varying flow rates and pressures. This adaptability enables processors to fine-tune their operations according to production requirements. By adjusting the pump's speed and settings, companies can effectively manage their workflows, which is essential for meeting market demands without compromising quality.

Moreover, rotary lobe pumps are known for their durability and reliability. Constructed from high-quality materials, they can withstand the demanding conditions of meat and poultry processing, including temperature variations and corrosive cleaning agents. This longevity translates into lower maintenance costs and less frequent replacements, which can significantly enhance overall operational efficiency.

In conclusion, rotary lobe pumps play a vital role in meat and poultry processing by providing gentle, efficient, and hygienic product transfer. Their versatility, ease of cleaning, and robustness make them an invaluable asset in modern food processing facilities. For businesses looking to optimize their operations, investing in rotary lobe pumps can lead to improved productivity and enhanced product quality. Understanding these benefits can help decision-makers in the industry make informed choices that align with their operational goals.

PREVIOUS:

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai