Maximizing Efficiency: Rotary Lobe Pumps for Syrup and Molasses in Industry

Oct 21,2025

Maximizing Efficiency: Rotary Lobe Pumps for Syrup and Molasses in Industry

In the ever-evolving landscape of industrial equipment, the choice of pump technology plays a pivotal role in optimizing processes and enhancing productivity. When it comes to handling viscous materials like syrup and molasses, rotary lobe pumps emerge as a highly efficient solution. This article delves deep into the attributes, benefits, applications, and maintenance practices associated with rotary lobe pumps, providing a comprehensive resource for industries reliant on these vital components.

Table of Contents

- 1. Introduction to Rotary Lobe Pumps

- 2. Why Choose Rotary Lobe Pumps for Syrup and Molasses?

- 3. How Rotary Lobe Pumps Work

- 4. Key Benefits of Rotary Lobe Pumps

- 5. Applications of Rotary Lobe Pumps in Various Industries

- 6. Installation and Maintenance Best Practices

- 7. The Future of Rotary Lobe Pump Technology

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Rotary Lobe Pumps

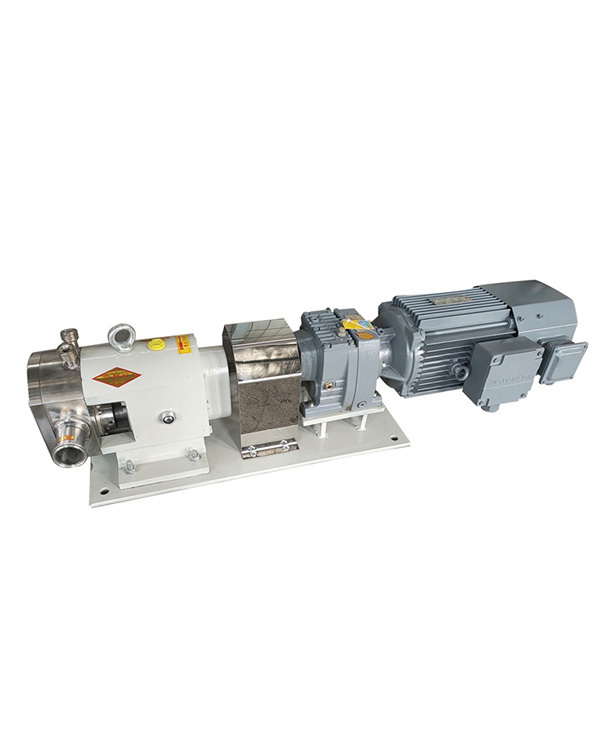

Rotary lobe pumps are positive displacement pumps that utilize two or more lobes to move fluids efficiently. Their design allows for the gentle pumping of viscous fluids, making them particularly well-suited for syrup and molasses applications. These pumps are increasingly favored due to their reliability, versatility, and ability to handle shear-sensitive materials without degradation.

2. Why Choose Rotary Lobe Pumps for Syrup and Molasses?

When dealing with syrup and molasses, industries face unique challenges. These products are often thick, sticky, and sensitive to shear, which can lead to quality degradation during processing. Rotary lobe pumps offer distinct advantages, including:

- Consistent flow rates, ensuring uniformity in product quality.

- Reduced shear forces, preserving the integrity of sensitive ingredients.

- Versatile operation across varying viscosities, adapting to fluctuating production needs.

3. How Rotary Lobe Pumps Work

The operational mechanics of rotary lobe pumps are straightforward yet highly effective. The lobes rotate in synchrony, creating a series of chambers that draw in fluid and transport it through the pump. As the lobes rotate, they create suction on the inlet side and compress the fluid on the discharge side. This positive displacement mechanism ensures minimal pulsation and a steady flow, essential for applications requiring precise control.

4. Key Benefits of Rotary Lobe Pumps

4.1 High Efficiency and Performance

Rotary lobe pumps are designed for optimal efficiency, often achieving higher flow rates with lower energy consumption compared to traditional pump designs. This efficiency translates into cost savings and improved operational performance, essential for industries managing large volumes of syrup and molasses.

4.2 Gentle Handling of Products

One of the standout features of rotary lobe pumps is their ability to handle sensitive materials without compromising quality. The gentle pumping action minimizes shear stress, making them ideal for maintaining the viscosity and flavor profiles of syrups and molasses.

4.3 Ease of Maintenance

Maintenance is a critical aspect of any industrial equipment, and rotary lobe pumps excel in this area. Their modular design allows for quick disassembly and reassembly, facilitating easy inspection and maintenance. With fewer moving parts, the likelihood of mechanical failure is reduced, ensuring increased uptime and reliability.

5. Applications of Rotary Lobe Pumps in Various Industries

Rotary lobe pumps find applications in diverse sectors, including food and beverage, pharmaceuticals, and chemical industries. Their versatility makes them suitable for:

- Food and Beverage: Used for transferring syrups, molasses, and other viscous food products.

- Chemicals: Ideal for moving thick slurries and chemical mixtures without degradation.

- Pharmaceuticals: Ensures the hygienic transfer of sensitive formulations.

6. Installation and Maintenance Best Practices

Proper installation and maintenance of rotary lobe pumps are essential to maximize their efficiency and lifespan. Here are some best practices:

- Ensure alignment and leveling during installation to prevent undue stress on components.

- Regularly inspect seals and gaskets for wear and replace them as necessary to prevent leaks.

- Maintain a clean operating environment to minimize contamination risks.

- Utilize manufacturer-recommended lubricants and follow maintenance schedules diligently.

7. The Future of Rotary Lobe Pump Technology

The future of rotary lobe pumps is poised for innovation, with advancements in materials, design, and automation. Manufacturers are exploring lightweight materials for improved efficiency and introducing smart technologies for real-time monitoring and diagnostics. These innovations aim to enhance the adaptability and performance of rotary lobe pumps in increasingly demanding industrial environments.

8. Frequently Asked Questions (FAQs)

1. What is the primary advantage of using rotary lobe pumps for syrup and molasses?

The primary advantage is their ability to handle viscous materials with minimal shear, preserving product quality while ensuring consistent flow rates.

2. How do I determine the appropriate size of rotary lobe pump for my application?

The appropriate size depends on the viscosity of the fluid, the required flow rate, and the specific application requirements. Consulting with a pump specialist is recommended.

3. What maintenance practices should be followed for rotary lobe pumps?

Regular inspection, cleaning, and monitoring of wear parts like seals and gaskets are crucial. Following the manufacturer’s maintenance guidelines will enhance pump longevity.

4. Can rotary lobe pumps handle shear-sensitive products?

Yes, rotary lobe pumps are designed to handle shear-sensitive products gently, making them ideal for applications involving syrups and molasses.

5. Are rotary lobe pumps energy-efficient?

Yes, rotary lobe pumps are known for their high efficiency and low energy consumption compared to other pump types, leading to cost savings in industrial operations.

9. Conclusion

In conclusion, rotary lobe pumps represent a robust solution for industries handling syrup and molasses. Their unique design, efficiency, and gentle handling capabilities set them apart in the realm of industrial pumps. By understanding the benefits and best practices associated with these pumps, companies can significantly enhance their operational efficiency, product quality, and overall productivity. As technology advances, rotary lobe pumps will continue to evolve, ensuring they remain a vital component in modern industrial processes.

PREVIOUS:

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai