What Makes Rotary Lobe Pumps Ideal for Syrups and Molasses?

Nov 30,2025

What Makes Rotary Lobe Pumps Ideal for Syrups and Molasses?

Table of Contents

- 1. Introduction

- 2. Understanding Rotary Lobe Pumps

- 3. Benefits of Using Rotary Lobe Pumps for Syrups and Molasses

- 3.1 Gentle Handling of Viscous Fluids

- 3.2 Self-Priming Capabilities

- 3.3 Ease of Maintenance

- 3.4 Versatility in Design

- 4. Applications in the Food Industry

- 5. Comparison with Other Pump Types

- 6. Frequently Asked Questions

- 7. Conclusion

1. Introduction

In the ever-evolving landscape of food processing, selecting the right pumping solution is crucial for efficiency and product quality. **Rotary lobe pumps** are gaining popularity in this field, particularly for handling viscous substances such as **syrups** and **molasses**. This article delves into the workings of rotary lobe pumps, their benefits, and why they are the preferred choice for industries processing high-viscosity fluids.

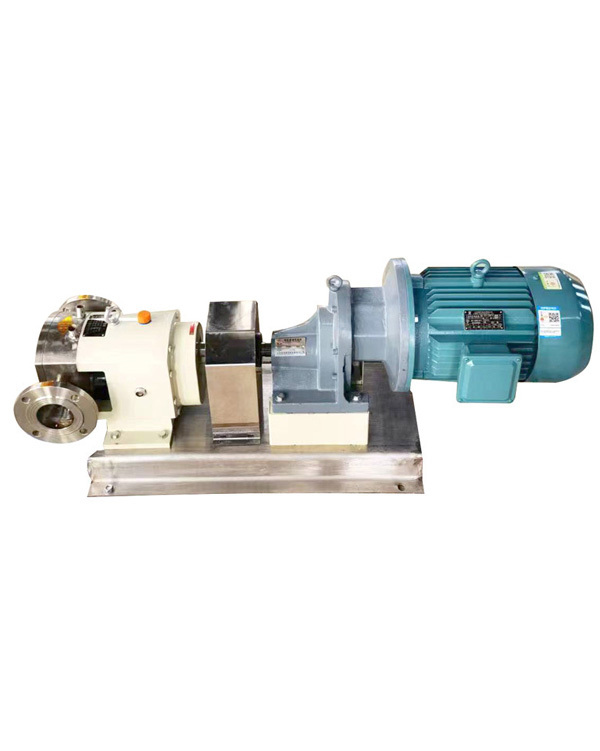

2. Understanding Rotary Lobe Pumps

2.1 How They Work

Rotary lobe pumps function through the synchronous rotation of two or more lobes within a chamber. As these lobes rotate, they create expanding and contracting cavities that facilitate the movement of fluid through the pump. This design ensures a smooth and continuous flow, making it particularly suited for syrup and molasses applications where viscosity can vary significantly.

2.2 Key Components

The fundamental components of rotary lobe pumps include:

- **Lobes**: The primary mechanism that facilitates fluid movement. Typically, the lobes are made from materials resistant to wear and corrosion.

- **Casing**: Houses the lobes and maintains the necessary tolerances for efficient operation.

- **Drive Shaft**: Powers the lobes, usually connected to an electric motor.

- **Seals**: Critical for preventing leaks and maintaining pressure within the pump.

3. Benefits of Using Rotary Lobe Pumps for Syrups and Molasses

3.1 Gentle Handling of Viscous Fluids

One of the standout features of rotary lobe pumps is their ability to handle sensitive fluids with minimal shear. When processing syrups and molasses, preserving the integrity of these products is crucial. Rotary lobe pumps excel in this area, ensuring that the **viscosity** is maintained without introducing air or creating foam.

3.2 Self-Priming Capabilities

Another significant advantage of rotary lobe pumps is their self-priming nature. This characteristic allows them to effectively handle high-viscosity fluids without requiring additional priming systems, thereby reducing setup time and operational complexity. This feature is particularly beneficial in continuous production environments where downtime is costly.

3.3 Ease of Maintenance

Maintaining rotary lobe pumps is generally straightforward. Their simple design allows for easy disassembly and reassembly, facilitating quick repairs and maintenance. Additionally, the durable materials used in manufacturing these pumps minimize wear and tear, further enhancing their lifespan and reliability.

3.4 Versatility in Design

Rotary lobe pumps come in various designs and configurations, making them adaptable to different applications and environments. Whether it’s a sanitary design for food-grade applications or a robust model for industrial use, there’s a rotary lobe pump to meet specific needs.

4. Applications in the Food Industry

The versatility of rotary lobe pumps makes them ideal for a range of applications in the food industry beyond just syrups and molasses. They are equally effective in transferring sauces, jams, and even dairy products. Their ability to handle high viscosities without damaging the product makes them indispensable in food processing facilities.

5. Comparison with Other Pump Types

When comparing rotary lobe pumps to other types, such as diaphragm or centrifugal pumps, several key differences emerge:

- **Shear Sensitivity**: Rotary lobe pumps offer lower shear than centrifugal pumps, making them ideal for sensitive products like syrups and molasses.

- **Viscosity Handling**: While diaphragm pumps can handle viscous fluids, rotary lobe pumps generally provide a smoother flow and better efficiency.

- **Maintenance**: Rotary lobe pumps typically require less frequent maintenance compared to diaphragm pumps, leading to lower operational costs over time.

6. Frequently Asked Questions

What are the typical applications for rotary lobe pumps?

Rotary lobe pumps are primarily used for transferring viscous fluids such as syrups, molasses, sauces, and other food products requiring gentle handling.

How do rotary lobe pumps compare to centrifugal pumps?

Rotary lobe pumps are more efficient for high-viscosity fluids, offering lower shear and better handling of sensitive products compared to centrifugal pumps.

Are rotary lobe pumps easy to maintain?

Yes, rotary lobe pumps are designed for easy maintenance, allowing for quick disassembly and reassembly, which saves time and reduces downtime.

Can rotary lobe pumps handle abrasive materials?

While rotary lobe pumps can handle some abrasive materials, it is essential to choose the right materials for the lobes and casing to ensure longevity.

What materials are commonly used to manufacture rotary lobe pumps?

Rotary lobe pumps are typically made from stainless steel, rubber, and other durable materials that resist wear and corrosion, ensuring they last in demanding environments.

7. Conclusion

In conclusion, rotary lobe pumps stand out as the ideal solution for transferring syrups and molasses within the food processing industry. With their **gentle handling**, **self-priming capabilities**, and **ease of maintenance**, these pumps offer significant advantages over other types. Their versatility in design further enhances their appeal, making them an excellent choice for a variety of applications. As food processing demands continue to evolve, rotary lobe pumps will undoubtedly play a pivotal role in ensuring efficiency and product quality.

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai