Maximizing Efficiency with Rotary Lobe Pumps for High-Viscosity Liquids

Dec 12,2025

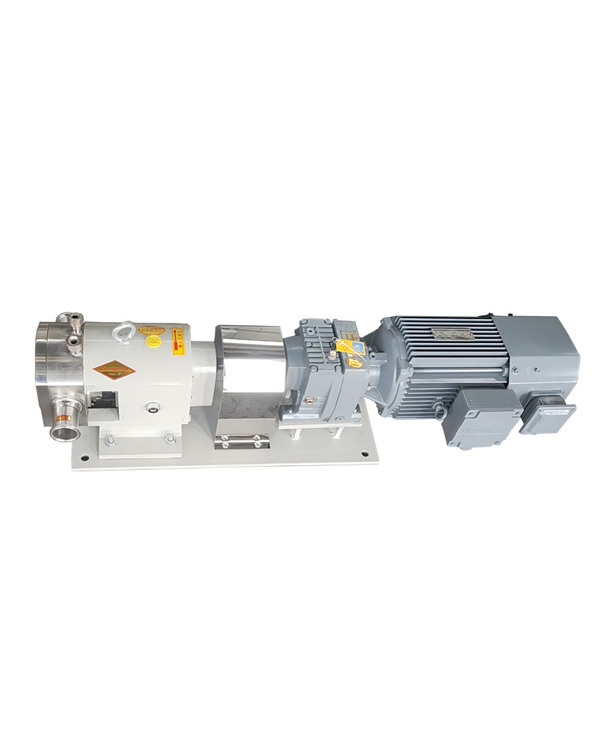

Rotary lobe pumps are engineered to handle a diverse array of fluids, particularly those with high viscosity, making them essential in many industrial sectors. These pumps operate using two or more lobes that rotate in synchronization, creating a series of sealed chambers that draw in and expel liquids. This unique design allows for the gentle handling of viscous fluids without shearing or damaging the product, which is particularly vital in industries such as food processing, pharmaceuticals, and chemical manufacturing.

One of the standout features of rotary lobe pumps is their ability to maintain a consistent flow rate, even when dealing with thick or sticky liquids. This is crucial in applications where precise fluid transfer is necessary, such as in the production of viscous food products like sauces or spreads, where maintaining the integrity and texture of the product is paramount. Additionally, their self-priming capabilities allow them to handle various viscosities without requiring complex setups, further enhancing their versatility.

In terms of maintenance, rotary lobe pumps are designed for ease of access and serviceability. Their modular design typically allows for quick disassembly, facilitating routine inspections and repairs without extensive downtime. This is particularly beneficial in high-volume environments where operational efficiency is key. Moreover, the wear-resistant materials used in the construction of these pumps contribute to their durability, ensuring a longer lifespan and reducing the frequency of replacements.

Another significant advantage of rotary lobe pumps is their adaptability to different operating conditions. Many models can be configured with variable speed drives, allowing users to adjust the flow rate according to specific process requirements. This flexibility not only enhances productivity but also contributes to energy efficiency, as the pump can operate optimally under varying load conditions.

When selecting a rotary lobe pump for high-viscosity applications, it’s essential to consider factors such as the fluid's temperature, the required flow rate, and the nature of the material being pumped. Ensuring compatibility with the pump's materials of construction can prevent damage and extend the pump's operational life.

In summary, rotary lobe pumps stand out as a reliable solution for transporting high-viscosity liquids across various industries. Their efficient operation, ease of maintenance, and adaptability make them an excellent choice for businesses looking to optimize their fluid handling processes while maintaining product quality. Investing in the right rotary lobe pump can significantly enhance operational efficiency and reduce costs in the long run, making them a critical component in any industrial fluid management strategy.

One of the standout features of rotary lobe pumps is their ability to maintain a consistent flow rate, even when dealing with thick or sticky liquids. This is crucial in applications where precise fluid transfer is necessary, such as in the production of viscous food products like sauces or spreads, where maintaining the integrity and texture of the product is paramount. Additionally, their self-priming capabilities allow them to handle various viscosities without requiring complex setups, further enhancing their versatility.

In terms of maintenance, rotary lobe pumps are designed for ease of access and serviceability. Their modular design typically allows for quick disassembly, facilitating routine inspections and repairs without extensive downtime. This is particularly beneficial in high-volume environments where operational efficiency is key. Moreover, the wear-resistant materials used in the construction of these pumps contribute to their durability, ensuring a longer lifespan and reducing the frequency of replacements.

Another significant advantage of rotary lobe pumps is their adaptability to different operating conditions. Many models can be configured with variable speed drives, allowing users to adjust the flow rate according to specific process requirements. This flexibility not only enhances productivity but also contributes to energy efficiency, as the pump can operate optimally under varying load conditions.

When selecting a rotary lobe pump for high-viscosity applications, it’s essential to consider factors such as the fluid's temperature, the required flow rate, and the nature of the material being pumped. Ensuring compatibility with the pump's materials of construction can prevent damage and extend the pump's operational life.

In summary, rotary lobe pumps stand out as a reliable solution for transporting high-viscosity liquids across various industries. Their efficient operation, ease of maintenance, and adaptability make them an excellent choice for businesses looking to optimize their fluid handling processes while maintaining product quality. Investing in the right rotary lobe pump can significantly enhance operational efficiency and reduce costs in the long run, making them a critical component in any industrial fluid management strategy.

PREVIOUS:

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai