Enhancing Meat and Poultry Processing with Rotary Lobe Pumps

Dec 30,2025

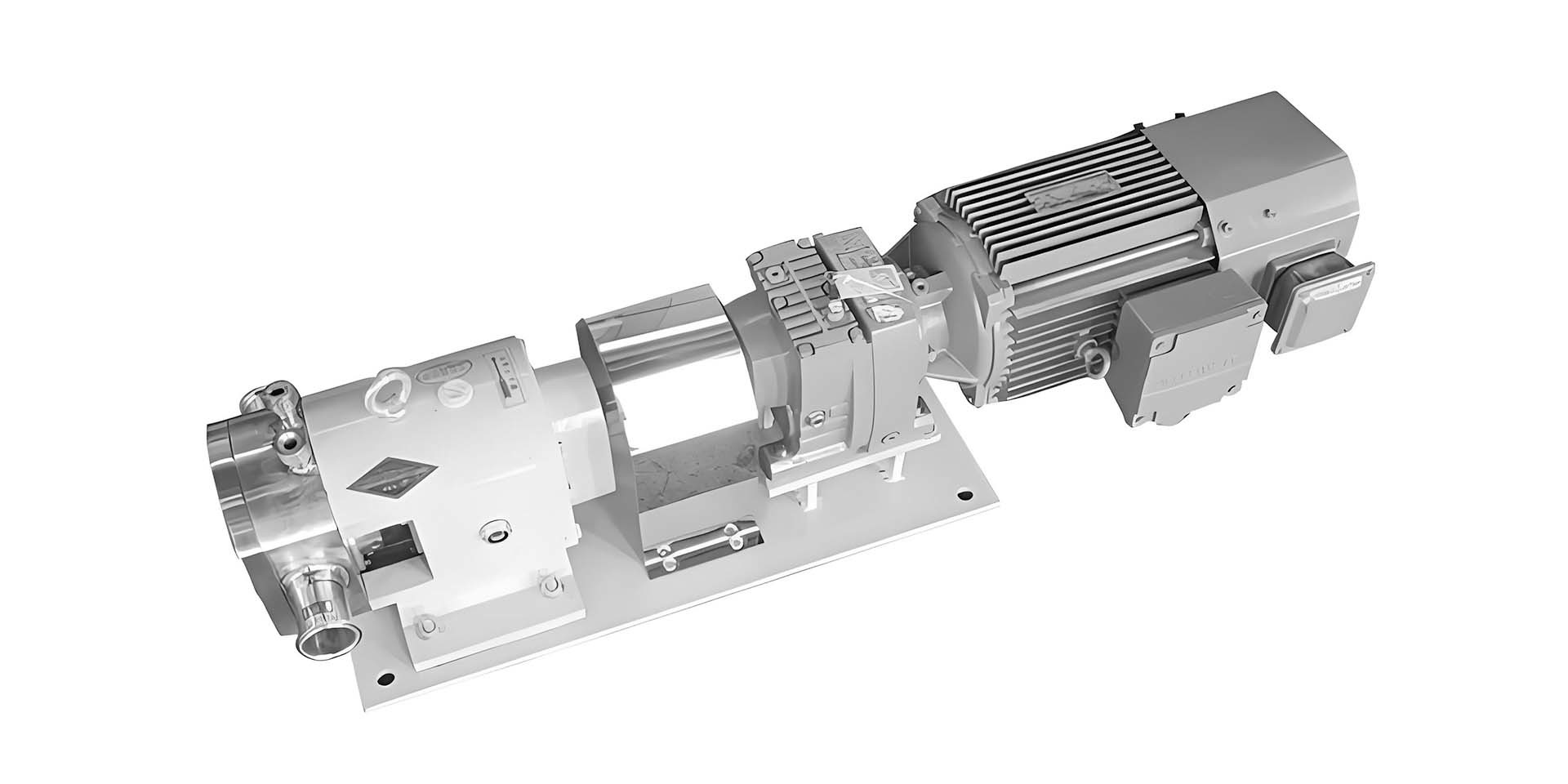

In the meat and poultry processing industry, maintaining the integrity and quality of products is paramount. One of the essential components that facilitate this process is the rotary lobe pump. These pumps are particularly well-suited for handling viscous and shear-sensitive materials, making them an ideal choice for transporting meat and poultry products.

Rotary lobe pumps operate using two or more lobes that rotate in a synchronized manner within a pump chamber. As the lobes turn, they create a series of pockets that draw in materials and then push them through the discharge line. This design ensures a gentle handling of the product, which is crucial for preserving the texture and quality of meat and poultry. Unlike other pump types, rotary lobe pumps are not only efficient but also provide a continuous flow, minimizing the risk of product damage.

One of the most significant advantages of rotary lobe pumps in the meat and poultry processing sector is their hygienic design. Many models are constructed with materials that meet food safety standards, ensuring that there is no contamination during the pumping process. The ability to disassemble these pumps easily for thorough cleaning further enhances their appeal in environments where hygiene is critical.

Moreover, rotary lobe pumps excel in maintaining a consistent flow rate regardless of the viscosity of the product. This feature is particularly beneficial when dealing with varying consistencies, such as emulsified meats or marinades. By ensuring a steady flow, these pumps contribute to a more uniform product and can help reduce waste during processing.

When considering rotary lobe pumps for meat and poultry processing, it is essential to pay attention to several key factors. Firstly, the size and capacity of the pump should align with the specific needs of the operation. Over-sizing or under-sizing can lead to inefficiencies and potential operational issues. Secondly, compatibility with the processing system is crucial; ensuring that the pump can integrate seamlessly with existing equipment will optimize performance.

Lastly, regular maintenance is vital to ensure the longevity and efficiency of rotary lobe pumps. Implementing a routine maintenance schedule can prevent unexpected breakdowns and maintain optimal performance levels. This proactive approach not only extends the lifespan of the pump but also supports uninterrupted processing operations.

In conclusion, rotary lobe pumps offer numerous advantages for meat and poultry processing, including gentle product handling, hygienic design, and consistent performance. By understanding the operational principles and maintenance requirements, processors can leverage these pumps to enhance their efficiency and product quality, ensuring compliance with industry standards while meeting consumer expectations.

Rotary lobe pumps operate using two or more lobes that rotate in a synchronized manner within a pump chamber. As the lobes turn, they create a series of pockets that draw in materials and then push them through the discharge line. This design ensures a gentle handling of the product, which is crucial for preserving the texture and quality of meat and poultry. Unlike other pump types, rotary lobe pumps are not only efficient but also provide a continuous flow, minimizing the risk of product damage.

One of the most significant advantages of rotary lobe pumps in the meat and poultry processing sector is their hygienic design. Many models are constructed with materials that meet food safety standards, ensuring that there is no contamination during the pumping process. The ability to disassemble these pumps easily for thorough cleaning further enhances their appeal in environments where hygiene is critical.

Moreover, rotary lobe pumps excel in maintaining a consistent flow rate regardless of the viscosity of the product. This feature is particularly beneficial when dealing with varying consistencies, such as emulsified meats or marinades. By ensuring a steady flow, these pumps contribute to a more uniform product and can help reduce waste during processing.

When considering rotary lobe pumps for meat and poultry processing, it is essential to pay attention to several key factors. Firstly, the size and capacity of the pump should align with the specific needs of the operation. Over-sizing or under-sizing can lead to inefficiencies and potential operational issues. Secondly, compatibility with the processing system is crucial; ensuring that the pump can integrate seamlessly with existing equipment will optimize performance.

Lastly, regular maintenance is vital to ensure the longevity and efficiency of rotary lobe pumps. Implementing a routine maintenance schedule can prevent unexpected breakdowns and maintain optimal performance levels. This proactive approach not only extends the lifespan of the pump but also supports uninterrupted processing operations.

In conclusion, rotary lobe pumps offer numerous advantages for meat and poultry processing, including gentle product handling, hygienic design, and consistent performance. By understanding the operational principles and maintenance requirements, processors can leverage these pumps to enhance their efficiency and product quality, ensuring compliance with industry standards while meeting consumer expectations.

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai