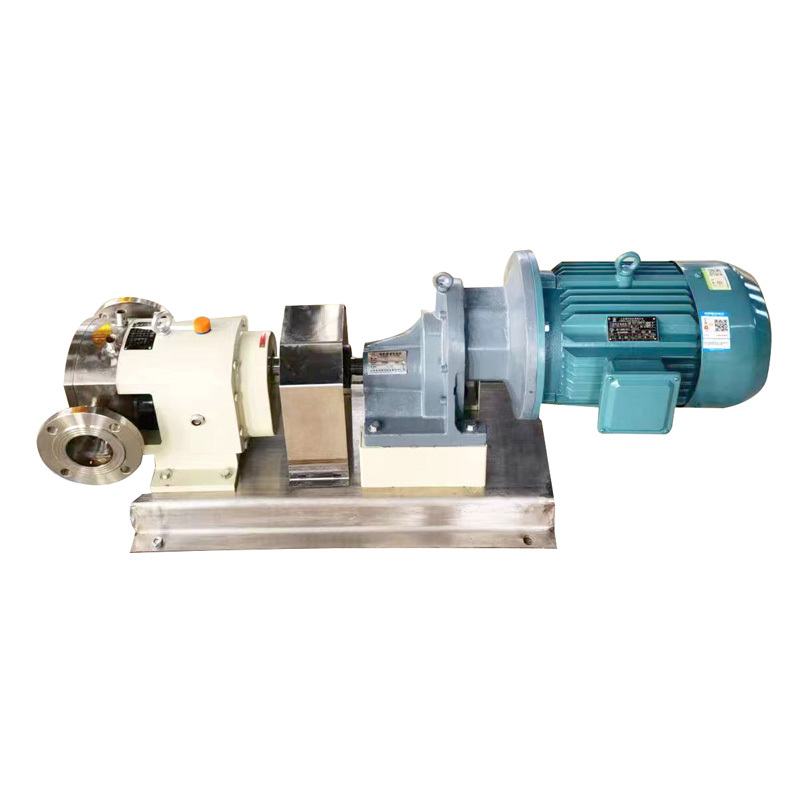

Twin screw pump is a positive displacement pump that uses two screws to move fluids or sludge through a chamber. The intermeshing of the two rotors form volumetric chambers, and these chambers fill with fluid that is carried from the suction side to the higher-pressure discharge side of the pump. This type of pump is often used in viscous applications or when high pressures are required.

• Delivery rate: up to 108 m³/h 475 gpm)

• Delivery head: up to 100 m 488 ft)

• Pressure: up to 16 bar (232 psi)

• Viscosities: up to 1,000,000CP

• Temperatures: 200 °C (392 °F)

• pH-value: 0 – 14

• Solids: max. 43 mm

•Solid liquid gas mixed transport possible

• Installations: horizontal, vertical

• Self-priming possible

• Single and double mechanical seal

• ATEX: Ex Zones 2 & 1

• ISO, CE,FDA standard

• hygienic design possible

• Drives: electro, hydraulic

Advantages Of Twin Screw Pumps

• Pulsation-free: constant pulsation-free liquid flow

• Viscosity range: maximum viscosity of 1,000,000 mPas

• Capacity: maximum capacity of 108 m3/h

• Busy: maximum working pressure of 16 bar

• NPSH: low NPSH required

• Hygiene: quick and easy to clean manually

• Vulnerable media: very suitable for fragile and shear sensitive products

• CIP: product and CIP with one pump (no additional CIP pump required)

• High suction capacity(self-primi

Application Areas

•Food & Beverage

•Dairy

•Pharmaceutical / Cosmetics

•Chemicals / Industrial

| SLGYQ Twin Screw Pump Parameter Table |

||||||

| Model | Flow m3/h |

Pressure MPa |

Maximum speed r/min |

Maximum particle MM |

Caliber mm |

Recommended power KW |

| SLGYQA3-1.6 | 3 | 1.6 | 0-1450 | 6 | 25-40 | 0.55-4 |

| SLGYQA5-1.2 | 5 | 1.2 | 0-1450 | 11 | 25-40 | 0.55-4 |

| SLGYQA8-0.8 | 8 | 0.8 | 0-1450 | 15 | 25-40 | 0.75-4 |

| SLGYQB9-1.6 | 9 | 1.6 | 0-1450 | 12 | 40-65 | 1.5-7.5 |

| SLGYQB12-1.2 | 12 | 1.2 | 0-1450 | 16 | 40-65 | 1.5-7.5 |

| SLGYQB18-0.8 | 18 | 0.8 | 0-1450 | 24 | 40-65 | 1.5-7.5 |

| SLGYQB22-0.6 | 22 | 0.6 | 0-1450 | 15 | 40-65 | 2.2-11 |

| SLGYQB28-0.5 | 28 | 0.5 | 0-1450 | 32 | 65-80 | 2.2-18 |

| SLGYQC23-1.6 | 23 | 1.6 | 0-1450 | 16 | 65-80 | 4-22 |

| SLGYQC30-1.2 | 30 | 1.2 | 0-1450 | 21 | 65-80 | 4-22 |

| SLGYQC46-0.8 | 46 | 0.8 | 0-1450 | 32 | 65-80 | 4-22 |

| SLGYQC58-0.6 | 58 | 0.6 | 0-1450 | 20 | 65-80 | 7.5-30 |

| SLGYQC61-0.6 | 61 | 5.5 | 0-1450 | 42 | 80-100 | 7.5-30 |

| SLGYQD53-1.6 | 53 | 1.6 | 0-1450 | 21 | 80-100 | 7.5--45 |

| SLGYQD72-1.2 | 72 | 1.2 | 0-1450 | 29 | 80-100 | 7.5-45 |

| SLGYQD108-0.8 | 108 | 0.8 | 0-1450 | 43 | 100-125 | 7.5-45 |

The Twin Screw Pump is a highly efficient and reliable fluid transfer device, widely used in various industries for its superior performance and versatility. This innovative pump features two intermeshing screws that work in tandem to move fluids with precision and minimal pulsation.

One of the key advantages of the Twin Screw Pump is its ability to handle a wide range of fluids, including viscous and shear-sensitive materials. The pump's design ensures gentle handling of fluids, preserving their integrity and preventing degradation. This makes it an ideal choice for applications in the food, pharmaceutical, and chemical industries.

The Twin Screw Pump operates with remarkable efficiency, thanks to its precise engineering and high-quality materials. The intermeshing screws create a continuous flow path, reducing the risk of cavitation and ensuring smooth, consistent fluid transfer. Additionally, the pump's self-priming capability allows for easy startup and operation, even with difficult fluids.

Durability is another hallmark of the Twin Screw Pump. Constructed from robust materials, the pump can withstand high pressures and temperatures, making it suitable for demanding industrial environments. Its low maintenance requirements and long service life further enhance its cost-effectiveness and reliability.

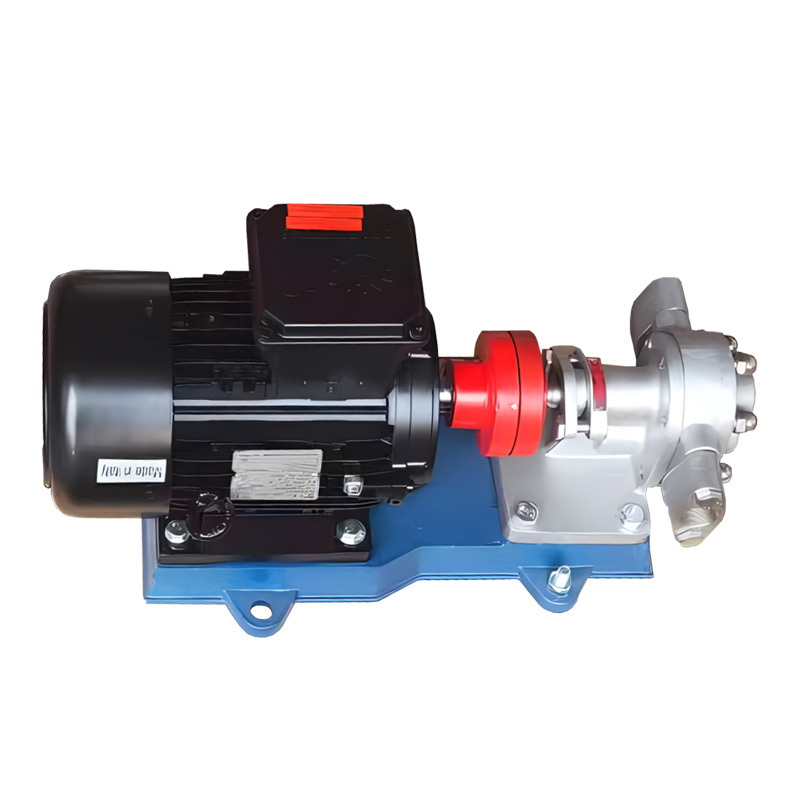

Keywords:Flexible pump | Rotary pump series | Magnetic pump | Screw pump | Gear pump

Get A Quote

If you are interested in our products, please leave your email to receive a free product quote. Thank you!