A gear pump is a type of positive displacement (PD) pump. It moves a fluid by repeatedly enclosing a fixed volume using interlocking cogs or gears, transferring it mechanically using a cyclic pumping action.

• Delivery rate: 0.4 to 72 m³/h (1.8 to 317 gpm)

• Delivery head: 5 to 45 m (16.4 to 148 ft)

• Pressure: up to 10 bar (145 psi)

• Viscosity: up to 5,000 mPas

• Temperature: -20 °C up to +200 °C (-680 °F up to +6760 °F)

• pH-value: 0 – 14

• Solids: max. 1 % (max. 6 mm)

• Installation: horizontal

• self-priming possible

• sealless

• ATEX (Ex Zone 1 & 2)

• Drives: electro, hydraulic

Advantages of gear pumps

1. Simple and compact structure, small volume, light weight, small space occupied.

2. good workmanship, easy to manufacture, inexpensive.

3. strong self-absorption, insensitive to fluid contamination, suitable for conveying high viscosity fluids.

4. large speed range, shock load resistance.

5. reliable operation, low maintenance costs.

Application Areas

The individual media that can be conveyed with gear pumps include, among others:

• Chemical industry: alcohols, additives, bitumen, tars, wax, acids and bases, esters, glycerin, resins, isocyanate, adhesives, monomers, oils, and phenols

• Polymer manufacturing and processing: PET, PBT, PS, ABS, PVC, PE, PEEK, cellulose, nylon, and other polymers

• Food / feed processing: plant oils, butter and margarine, flavorings, chocolate, licorice, chewing gum mass, syrup, honey, gelatins, mustard and ketchup, sugar solutions, enzymes

• Pharmacy: amino acids, lotion, shampoo, vitamins

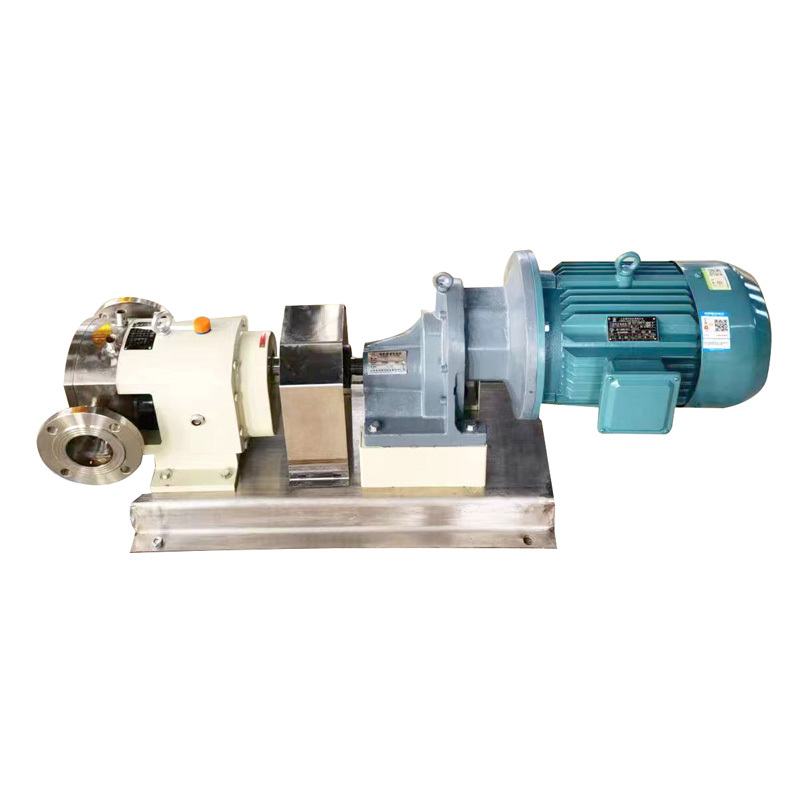

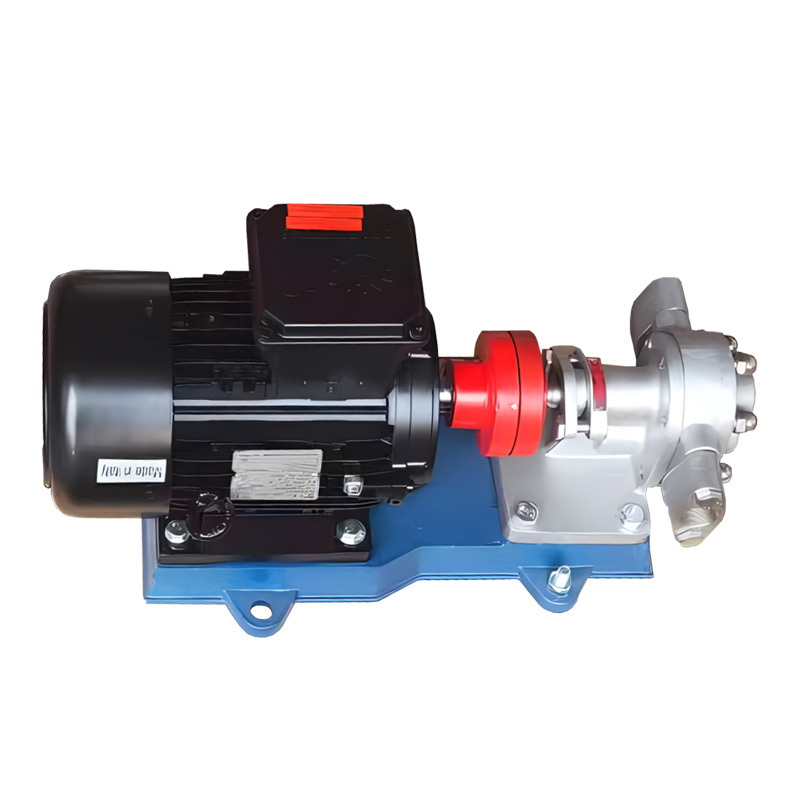

The Industrial Rotary Gear Pump represents a cornerstone of fluid handling technology in demanding process environments. As a type of positive displacement pump, the Industrial Rotary Gear Pump operates by using two or more interlocking gears to mechanically move fluid. As the gears rotate, they unmesh on the inlet side, creating a void and drawing fluid into the pump. This fluid is then trapped in the spaces between the gears and the casing, transported around the chamber, and forcibly discharged as the gears remesh on the outlet side. This precise, cyclic pumping action ensures a smooth, non-pulsating flow that is largely independent of pressure changes, making it exceptionally reliable for metering and transfer duties.

Engineered for durability and versatility, this Industrial Rotary Gear Pump is constructed from robust materials capable of handling a vast spectrum of media, including high-viscosity fluids, corrosive chemicals, abrasive slurries, and sensitive food products. Its simple and compact design offers significant advantages, such as a small footprint, high volumetric efficiency, and powerful self-priming capabilities. The pump is designed to operate reliably with fluids of varying viscosities, from thin solvents to thick polymers and tars, while maintaining consistent performance. Key characteristics often include the ability to handle pressures up to 10 bar, temperatures from -20°C to +200°C, and viscosities up to 5,000 mPas. With options for sealless magnetic drives and ATEX certification for explosive atmospheres, this robust Industrial Rotary Gear Pump is an indispensable solution across the chemical, pharmaceutical, food processing, and polymer manufacturing industries, providing dependable service with minimal maintenance requirements.

Keywords:Flexible pump | Rotary pump series | Magnetic pump | Screw pump | Gear pump

KCB-33.3 Industrial Rotary Gear Pump

Delivery rate: 2.0m³/h

Pressure: 1.45Mpa

Caliber: 20

Contact Us

Classification

Get A Quote

If you are interested in our products, please leave your email to receive a free product quote. Thank you!