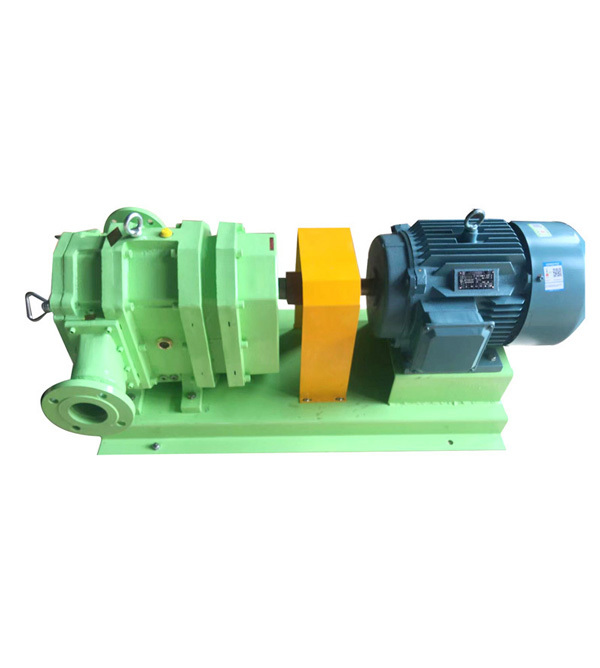

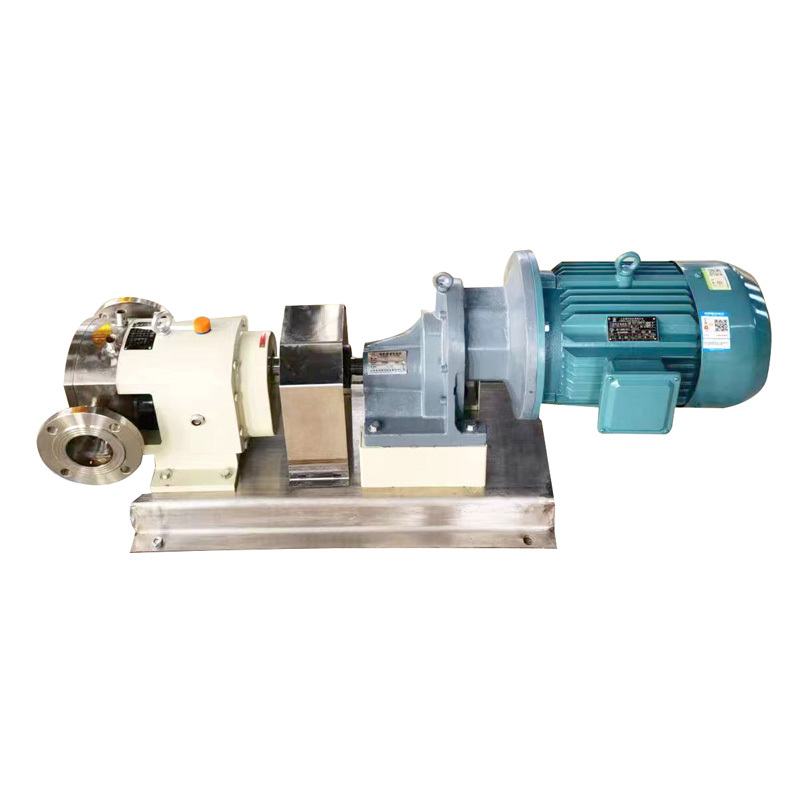

Rubber Rotary Lobe Pump is an Industrial Pump designed to transfer viscous, fibrous, abrasive and solid-laden products. Featuring reversible rotary design and rubber lobes, this self-priming pump offers exceptional performance a range of Industrial applications.

• Delivery rate: up to 500 m³/h (2202 gpm)

• Delivery head: up to 120 m (394 ft)

• Pressure: up to 15 bar (218 psi)

• Viscosities: up to 100,000 cSt

• Temperature: up to 130 °C

• pH-value: 4 – 10

• Gases: up to 95 %

• Solids: up to 60 % (max. 70 mm)

• Installations: horizontal, vertical

• Submersibilities: immersed, submerged

• Depth: up to 10 m (33 ft)

• self-priming possible

• ATEX: suitable for ExZones 1 & 2

• API, ISO, EN standard

• hygienic design available

• Drives: electro, diesel, hydraulic

Advantages of rubber lobe pumps

• Near pulseless, reversible flow

• Gentle product handling & low shear effect on fluid

• Self-Priming to 5m

• Replaceable Wear Plates at front and back of the pump housing in Wear Resistant Steel (400 HB)

• Hardened bushes as standard increase wear resistance & reliability in arduous and abrasive applications

• Bean-shaped lobes facilitate easier and smoother passage of solids

• Short Dry Running Capability thanks to Grease Lubricated Seals

• Seal Leakage Checking System enables quick and easy inspection

• Swan Neck Suction & Discharge Manifolds aide in Priming & and can be fitted with Pressure Gauges for a quick inspection of pump & system conditions. Drain & Vent Ports are also fitted as standard.

• Quick & Easy Lobe Maintenance & Inspection thanks to Front Pull-Out Design – Pump can be left in the pipework, Seals & Transmission system are left untouched.

Application Areas

Typical applications for our Industrial Rubber Rotary Lobe Pump:

• Petrochemical

• Mining and metallurgical industry

• Food processing industry

• Water treatment

• Shipping industry

| Viscosity & Rotary speed of pump | ||

| The running speed of the pump needs to be selected appropriately according to the viscosity of the medium, the higher the viscosity of the material, the lower the corresponding speed of the pump should be. The appropriate rotary speed will improve the efficiency of the pump, prolong the service life, and otherwise it will lead to pump operation cavitation, vibration and noise. | ||

| Viscosity | Suggested speed | Reference medium |

| 1~100cP | 30~60rpm | Clean water,oil |

| 1000~10000cP | 30~50rpm | Cooking oil,dish soap |

| 10000~50000cP | 15~20rpm | Paint, butter |

| 50000~100000cP | 10~15rpm | Asphalt,dehydrated sludge |

| >100000cP | 5~10rpm | Glue |

| Tip: cP is the unit of dynamic viscosity,with lcP=1/100P(poise)=l mpa · s | ||

| Solids content & Rotary speed of pump | ||

| The running speed of the pump needs to be selected according to the size of the solid rate of the medium, the higher the solid rate of the material, the lower the corresponding speed of the pump should be. The appropriate rotary speed will improve the efficiency of the pump and prolong the service life, on the contrary, it will lead to abnormal wear of the wearing parts of the pump, and the higher the solids content, the higher the cost of maintenance or replacement will be. | ||

| Viscosity | Suggested speed | Reference medium |

| Almost no wear material | 30~50rpm | Clean water,oil |

| Lightly worn material | 30~40rpm | 0rdinary sewage, solid content<3% |

| Medium wear material | 20~30rpm | Sedimentation tank sludge, solid content |

| Strong wear material | 15~20rpm | Sandy sludge,sewage |

| Heavy wear material | 10~15rpm | Lime mud,pulp |

| Tip:Solid content refers to the percentage of solids in the mixture (material) | ||

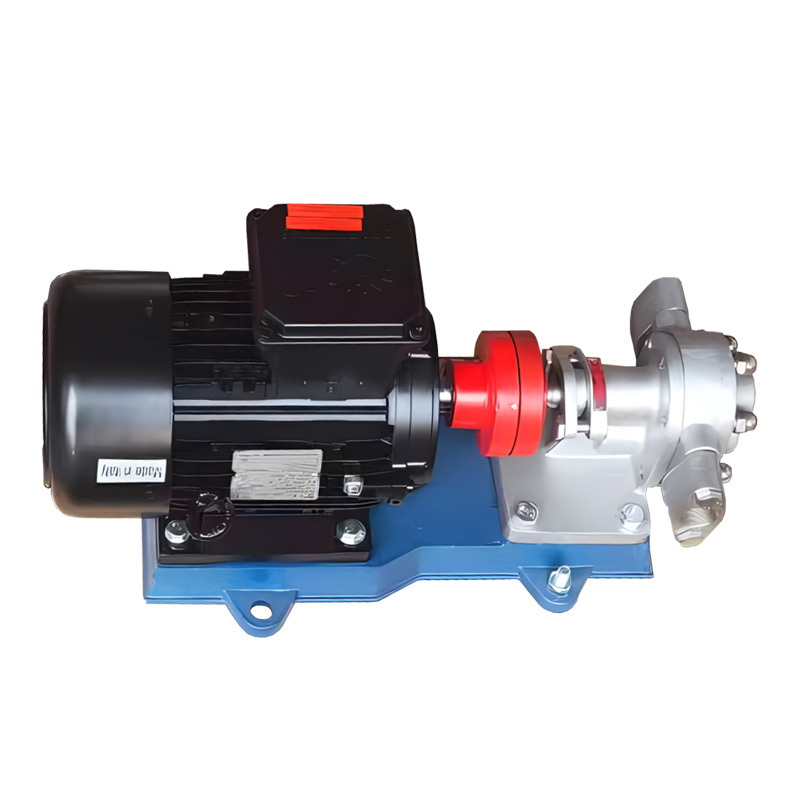

Keywords:Flexible pump | Rotary pump series | Magnetic pump | Screw pump | Gear pump

Get A Quote

If you are interested in our products, please leave your email to receive a free product quote. Thank you!