Hose pump, also known as peristaltic pump, can transport a variety of temperatures not higher than 100 ℃ of the liquid material, especially suitable for transporting some high-viscosity, high solid content, highly corrosive materials, as well as some of the larger solid particles containing longer fibers, or for the shear more sensitive materials. Widely used in metallurgy and mining, chemical industry, environmental protection, agriculture, tunnel engineering machinery, food, medicine and other industries.

• Delivery rate: up to 66 m³/h

• Delivery head: up to 100 m (328 ft)

• Pressure: up to 10 bar (145 psi)

• Viscosities: up to 50,000 mm²/sec

• Temperatures: 0 °C up to 80 °C (32 – 176 °F)

• pH-value: 0 – 14

• Gases: up to 99 %

• Solids: up to 80 % (max. 45 mm)

• Installations: horizontal, vertical

• self-priming possible

• sealless design possible

• ATEX: Ex Zones 2 & 1

• ISO, EN standard

• hygienic design possible

• Drives: electro, hydraulic

How Hose Pumps Work

Hose pumps are sometimes also called peristaltic pumps or squeeze pumps. Inside the hose pump, there is a hose, which is fed in a U-shape through the housing. To convey liquid, the pump hose is clamped by rollers, which turn on a rotor: The rotor’s movement causes the clamped point to move along the hose. The medium inside is thus conveyed through the inside of the pump hose from the intake side to the pressure side. So hose pumps belong to the positive displacement pumps.

Application Areas

With their flexible hose materials and wide spectrum of capacities, peristaltic pumps are suitable for use in many industries. These include:

• Chemical industry

• Mining

• Water & Wastewater

• Food & Pharmacy

Certification

Peristaltic Hose Pump is a versatile and efficient pump widely used in various industries for precise fluid transfer. This innovative pump operates on the principle of peristaltic action, ensuring gentle and pulse-free delivery of liquids.

The key feature of a Peristaltic Hose Pump is its unique working mechanism. It consists of a rotor with rollers that sequentially squeeze and release a flexible hose, creating a pumping action. This design allows for the complete containment of the fluid within the hose, eliminating the risk of contamination and ensuring high hygiene standards.

One of the major advantages of a Peristaltic Hose Pump is its ability to handle a wide range of fluids, including viscous, abrasive, and shear-sensitive materials. The gentle pumping action minimizes fluid degradation and maintains the integrity of delicate substances.

In addition, Peristaltic Hose Pumps offer excellent metering accuracy and repeatability. The precise control over the flow rate and volume makes them suitable for applications that require strict dosing and dispensing, such as in pharmaceutical and chemical industries.

The pump is also easy to clean and maintain. The hose can be quickly replaced without any tools, reducing downtime and ensuring continuous operation. Furthermore, the simple design with few moving parts enhances reliability and reduces the risk of mechanical failure.

Keywords:Flexible pump | Rotary pump series | Magnetic pump | Screw pump | Gear pump

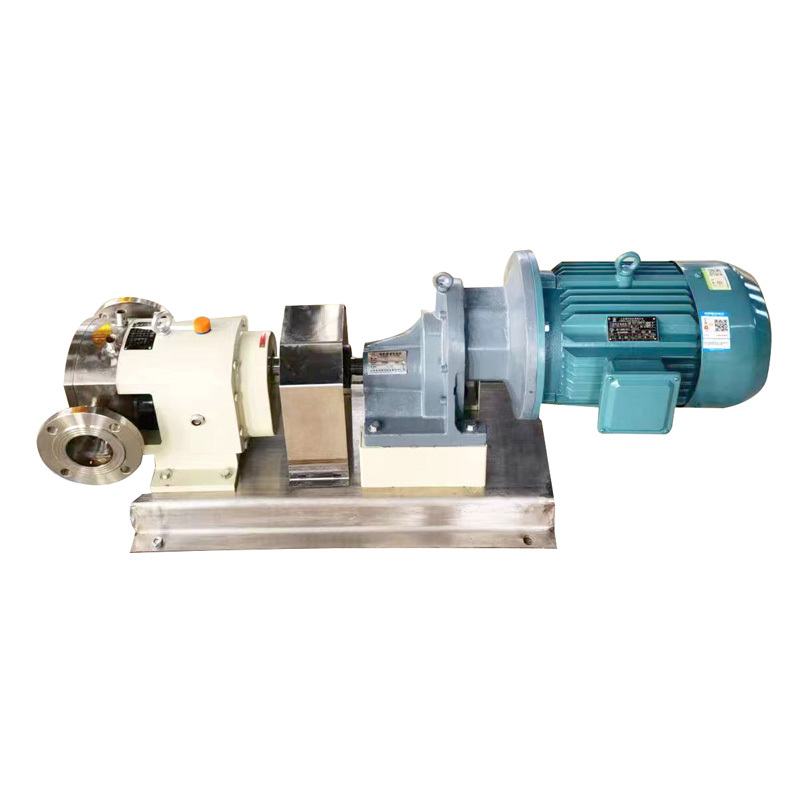

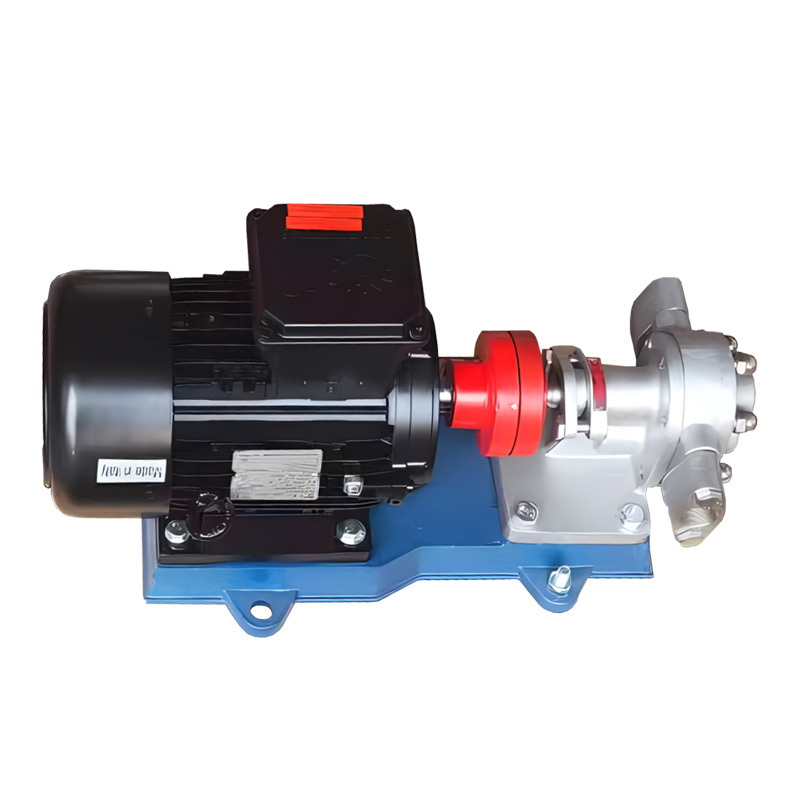

HXRB-15-20 Peristaltic Hose Pump

Delivery rate: 600-1020L/H

Pressure: 0.8Mpa

Caliber: 15/20

Contact Us

Classification

Get A Quote

If you are interested in our products, please leave your email to receive a free product quote. Thank you!