Understanding Rotary Lobe Pumps for High-Viscosity Liquids: A Comprehensive Guide

Nov 02,2025

---

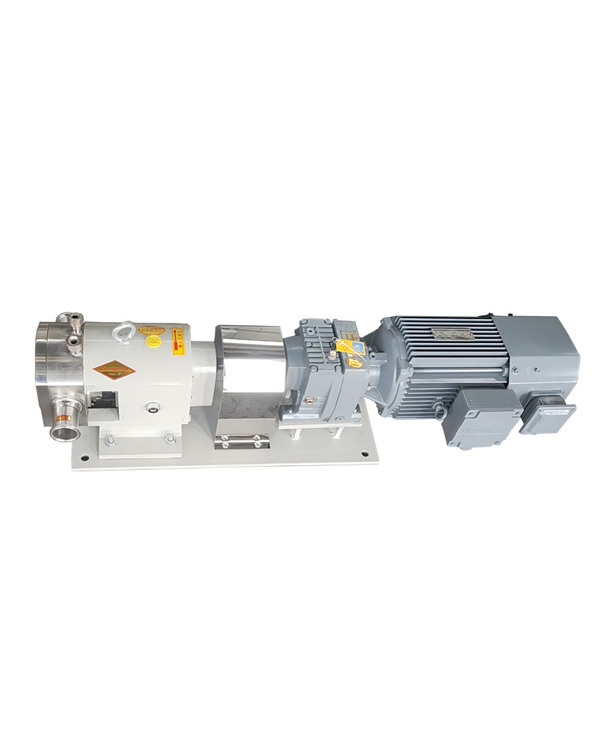

Rotary lobe pumps are increasingly recognized for their efficiency in transferring high-viscosity liquids across various industrial settings. Unlike traditional centrifugal pumps, rotary lobe pumps utilize two or more rotating lobes to create a positive displacement action, making them ideal for moving thick or viscous fluids with minimal shear and without damaging the product.

One of the primary advantages of rotary lobe pumps is their ability to handle a wide range of viscosities. They excel in transporting products such as viscous slurries, pastes, and even shear-sensitive materials like certain food products and polymers. This versatility allows industries like food and beverage, pharmaceuticals, and chemical processing to rely on rotary lobe pumps for consistent and reliable fluid transfer.

The design of a rotary lobe pump consists of two lobes that rotate in opposite directions within a casing. As the lobes turn, they create a series of chambers that expand and contract, enabling the pump to pull in liquid and then push it out through the discharge side. This positive displacement mechanism not only ensures a smooth flow but also maintains a constant flow rate, regardless of the pressure conditions. Consequently, rotary lobe pumps are particularly advantageous for applications requiring precise dosing and metering.

Another vital feature of rotary lobe pumps is their ease of maintenance. Many models are designed with serviceable components that allow for quick disassembly and cleaning, essential for industries where hygiene is paramount. The materials used in construction often comply with industry standards, allowing for the safe handling of food-grade and pharmaceutical products. This not only simplifies maintenance but also reduces downtime, enhancing overall operational efficiency.

When selecting a rotary lobe pump for high-viscosity liquids, there are several factors to consider. The type of lobes—such as single or double lobes—can significantly affect performance. The material of construction is crucial, particularly in corrosive environments or where contamination must be avoided. Additionally, understanding the pump's flow rate and pressure capabilities is essential for ensuring it meets the specific requirements of your application.

In conclusion, rotary lobe pumps are an excellent choice for industries that require the handling of high-viscosity liquids with precision and care. Their unique design, ease of maintenance, and operational efficiency make them a vital component in many industrial processes. By understanding the characteristics and benefits of these pumps, businesses can make informed decisions that enhance productivity and product quality.

Rotary lobe pumps are increasingly recognized for their efficiency in transferring high-viscosity liquids across various industrial settings. Unlike traditional centrifugal pumps, rotary lobe pumps utilize two or more rotating lobes to create a positive displacement action, making them ideal for moving thick or viscous fluids with minimal shear and without damaging the product.

One of the primary advantages of rotary lobe pumps is their ability to handle a wide range of viscosities. They excel in transporting products such as viscous slurries, pastes, and even shear-sensitive materials like certain food products and polymers. This versatility allows industries like food and beverage, pharmaceuticals, and chemical processing to rely on rotary lobe pumps for consistent and reliable fluid transfer.

The design of a rotary lobe pump consists of two lobes that rotate in opposite directions within a casing. As the lobes turn, they create a series of chambers that expand and contract, enabling the pump to pull in liquid and then push it out through the discharge side. This positive displacement mechanism not only ensures a smooth flow but also maintains a constant flow rate, regardless of the pressure conditions. Consequently, rotary lobe pumps are particularly advantageous for applications requiring precise dosing and metering.

Another vital feature of rotary lobe pumps is their ease of maintenance. Many models are designed with serviceable components that allow for quick disassembly and cleaning, essential for industries where hygiene is paramount. The materials used in construction often comply with industry standards, allowing for the safe handling of food-grade and pharmaceutical products. This not only simplifies maintenance but also reduces downtime, enhancing overall operational efficiency.

When selecting a rotary lobe pump for high-viscosity liquids, there are several factors to consider. The type of lobes—such as single or double lobes—can significantly affect performance. The material of construction is crucial, particularly in corrosive environments or where contamination must be avoided. Additionally, understanding the pump's flow rate and pressure capabilities is essential for ensuring it meets the specific requirements of your application.

In conclusion, rotary lobe pumps are an excellent choice for industries that require the handling of high-viscosity liquids with precision and care. Their unique design, ease of maintenance, and operational efficiency make them a vital component in many industrial processes. By understanding the characteristics and benefits of these pumps, businesses can make informed decisions that enhance productivity and product quality.

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai