Your Comprehensive Guide to 2CY Gear Pumps: Enhancing Hydraulic Oil Efficiency

Nov 06,2025

Your Comprehensive Guide to 2CY Gear Pumps: Enhancing Hydraulic Oil Efficiency

Table of Contents

1. Understanding 2CY Gear Pumps

2. Key Features of 2CY Gear Pumps

2.1 Design and Construction

2.2 Operating Principle

3. Advantages of Using 2CY Gear Pumps

3.1 High Efficiency

3.2 Low Maintenance Requirements

4. Applications of 2CY Gear Pumps

5. Maximizing Hydraulic Oil Efficiency

5.1 Choosing the Right Hydraulic Oil

5.2 Proper Installation Techniques

5.3 Regular Maintenance Practices

6. Troubleshooting Common Issues

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Understanding 2CY Gear Pumps

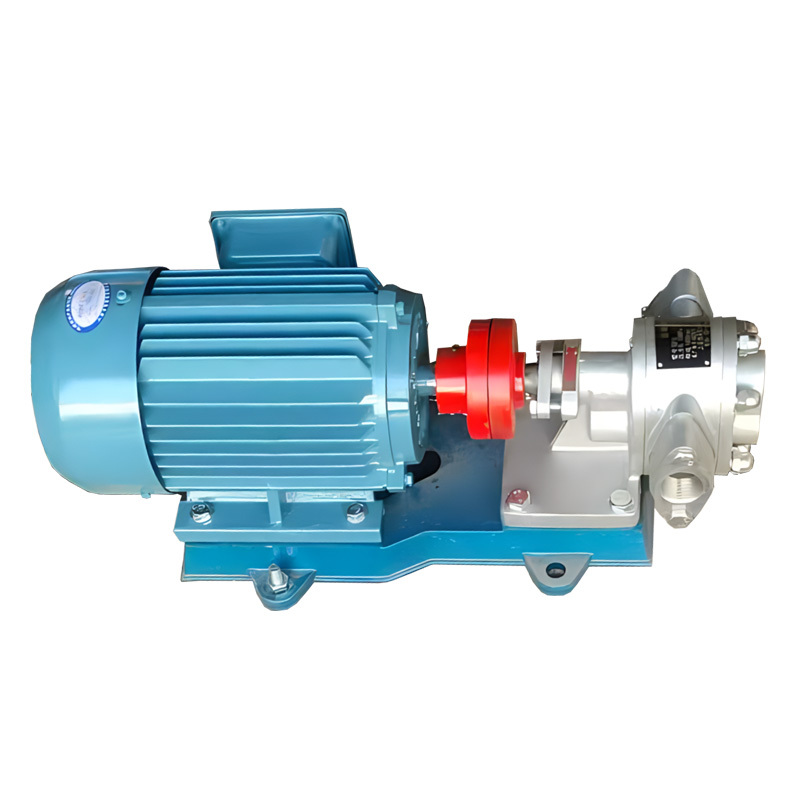

2CY gear pumps are a critical component in hydraulic systems across various industrial applications. These positive displacement pumps utilize two interlocking gears to transfer hydraulic oil, making them highly reliable and efficient. Understanding how these pumps work and their unique characteristics is vital for optimizing their performance.

2. Key Features of 2CY Gear Pumps

2.1 Design and Construction

The design of 2CY gear pumps typically features a robust construction that can endure high pressures and temperatures. They consist of two main gears enclosed within a housing, which allows for a smooth and continuous flow of hydraulic fluid. The materials used in the construction are crucial for durability and efficiency.

2.2 Operating Principle

The operating principle of 2CY gear pumps is based on the movement of gears. As the gears rotate, they create a vacuum that draws hydraulic oil into the pump. The oil is then trapped between the gear teeth and housing and pushed through the outlet, generating consistent pressure. This mechanism ensures minimal turbulence and optimal efficiency.

3. Advantages of Using 2CY Gear Pumps

Many industries prefer 2CY gear pumps due to their numerous advantages.

3.1 High Efficiency

2CY gear pumps are renowned for their high efficiency in transferring hydraulic oil. Their design minimizes energy loss during operation, allowing for improved performance in hydraulic systems.

3.2 Low Maintenance Requirements

These pumps require minimal maintenance compared to other types, making them cost-effective in the long run. Their simple design leads to fewer moving parts, reducing the likelihood of mechanical failure.

4. Applications of 2CY Gear Pumps

2CY gear pumps find applications in a variety of sectors, including:

- **Manufacturing**: Used in hydraulic presses and machines.

- **Automotive**: Employed in hydraulic steering systems and brake systems.

- **Agriculture**: Utilized in hydraulic systems for tractors and other equipment.

- **Oil and Gas**: Important for transporting crude oil and refined products.

5. Maximizing Hydraulic Oil Efficiency

To enhance the efficiency of hydraulic oil in 2CY gear pumps, several factors must be considered.

5.1 Choosing the Right Hydraulic Oil

Selecting the appropriate hydraulic oil is crucial for optimal performance. Factors such as viscosity, temperature stability, and compatibility with pump materials should be evaluated. A high-quality hydraulic oil can significantly improve pump efficiency and lifespan.

5.2 Proper Installation Techniques

Proper installation is essential to ensure the pump operates smoothly. Following manufacturer guidelines and ensuring proper alignment can prevent issues such as leaks and mechanical failures.

5.3 Regular Maintenance Practices

Implementing regular maintenance practices is vital for sustaining pump performance. This includes routine inspections, oil changes, and monitoring for wear and tear. Keeping the pump clean and free from debris also plays a significant role in maximizing efficiency.

6. Troubleshooting Common Issues

Despite their reliability, 2CY gear pumps may encounter certain problems. Common issues include:

- **Pressure fluctuations**: Often caused by air leaks or insufficient oil levels.

- **Increased noise levels**: May indicate wear in the gears or inadequate lubrication.

- **Overheating**: Can result from poor oil quality or blockages in the system.

Identifying these problems early can prevent costly repairs and downtime.

7. Frequently Asked Questions (FAQs)

1. What makes 2CY gear pumps different from other gear pumps?

2CY gear pumps feature a unique design that enhances efficiency and reduces maintenance requirements compared to traditional gear pumps.

2. How do I know if my 2CY gear pump needs maintenance?

Signs of wear, unusual noises, or decreased performance indicate that maintenance is necessary.

3. What type of hydraulic oil should I use for my 2CY gear pump?

Choose a hydraulic oil that matches the recommended viscosity and specifications provided by the manufacturer.

4. Can 2CY gear pumps handle high-pressure applications?

Yes, 2CY gear pumps are designed to operate effectively under high-pressure conditions, making them suitable for various industrial applications.

5. How can I extend the lifespan of my 2CY gear pump?

Regular maintenance, using high-quality hydraulic oil, and ensuring proper installation can significantly extend the lifespan of your gear pump.

8. Conclusion

In conclusion, understanding the intricacies of 2CY gear pumps and their role in maximizing hydraulic oil efficiency is essential for optimal performance in industrial applications. By focusing on the advantages, applications, and best practices for maintenance, we can ensure that these pumps operate efficiently and effectively. Investing time in the proper selection of hydraulic oil, careful installation, and routine maintenance will lead to enhanced performance and longevity of your 2CY gear pumps, ultimately benefiting your operations.

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai