Optimizing Meat and Poultry Processing with Rotary Lobe Pumps

Nov 18,2025

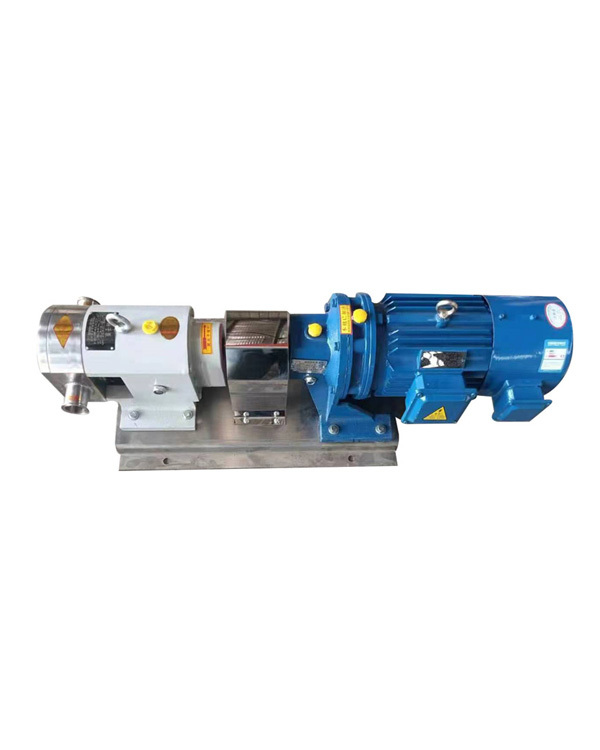

When it comes to the meat and poultry processing industry, the choice of equipment plays a crucial role in ensuring efficiency, hygiene, and product integrity. One equipment type that has gained traction in this sector is the rotary lobe pump. These pumps are specifically designed to handle the unique challenges presented by meat and poultry processing, making them an excellent choice for manufacturers aiming to optimize their operations.

Rotary lobe pumps operate using a pair of lobes that rotate in opposite directions, creating a chamber that moves fluid from the inlet to the outlet. This design allows for gentle handling of delicate products, which is particularly important in the meat and poultry sector where maintaining product integrity is paramount. Unlike other types of pumps, rotary lobe pumps can move viscous, thick, or shear-sensitive fluids without causing damage, ensuring that meat and poultry products retain their quality during processing.

One significant advantage of rotary lobe pumps in meat and poultry processing is their hygienic design. These pumps are typically constructed from materials that meet stringent food safety standards, reducing the risk of contamination. Moreover, they are easy to clean and maintain, which is essential in an industry where sanitization is critical. The smooth surfaces and simple disassembly of rotary lobe pumps facilitate thorough cleaning, helping processors adhere to regulatory requirements and maintain high hygiene standards.

Another benefit of using rotary lobe pumps is their ability to handle a wide range of flow rates and pressures. This versatility allows processors to use the same pump for various applications, such as transferring slurries, handling brines, or even dosing ingredients. This adaptability not only streamlines operations but also reduces the need for multiple types of pumps in a processing facility, leading to cost savings and more efficient use of space.

Furthermore, rotary lobe pumps are known for their reliability and durability. With fewer moving parts compared to other pump types, they are less prone to wear and tear, resulting in lower maintenance costs and reduced downtime. This reliability is essential in the fast-paced environment of meat and poultry processing, where any delays can lead to significant operational inefficiencies.

In conclusion, rotary lobe pumps represent a powerful solution for meat and poultry processing applications. Their gentle handling, hygienic design, versatility, and reliability make them an invaluable asset for processors looking to enhance efficiency and maintain product quality. By investing in rotary lobe pumps, companies in the meat and poultry sector can ensure that they meet industry standards while optimizing their production processes.

Contact Us

E-mail :

sales@yaquanpump.com

service@yaquanpump.com

Phone/WhatsApp:

+44 7301702546

+63 9452052801

Address:

Room B208, Building 2, North Hongqiao Songri Center, No.215 Gaochao Road, Jiading District, Shanghai